Re: Emergency Engine Teardown Thread

Posted: Sun Nov 20, 2011 9:06 pm

Isn't there anybody left that actually double-checks their work??? So sad!!!

Tech and Community Help For Air-Cooled VWs

https://itinerant-air-cooled.com/

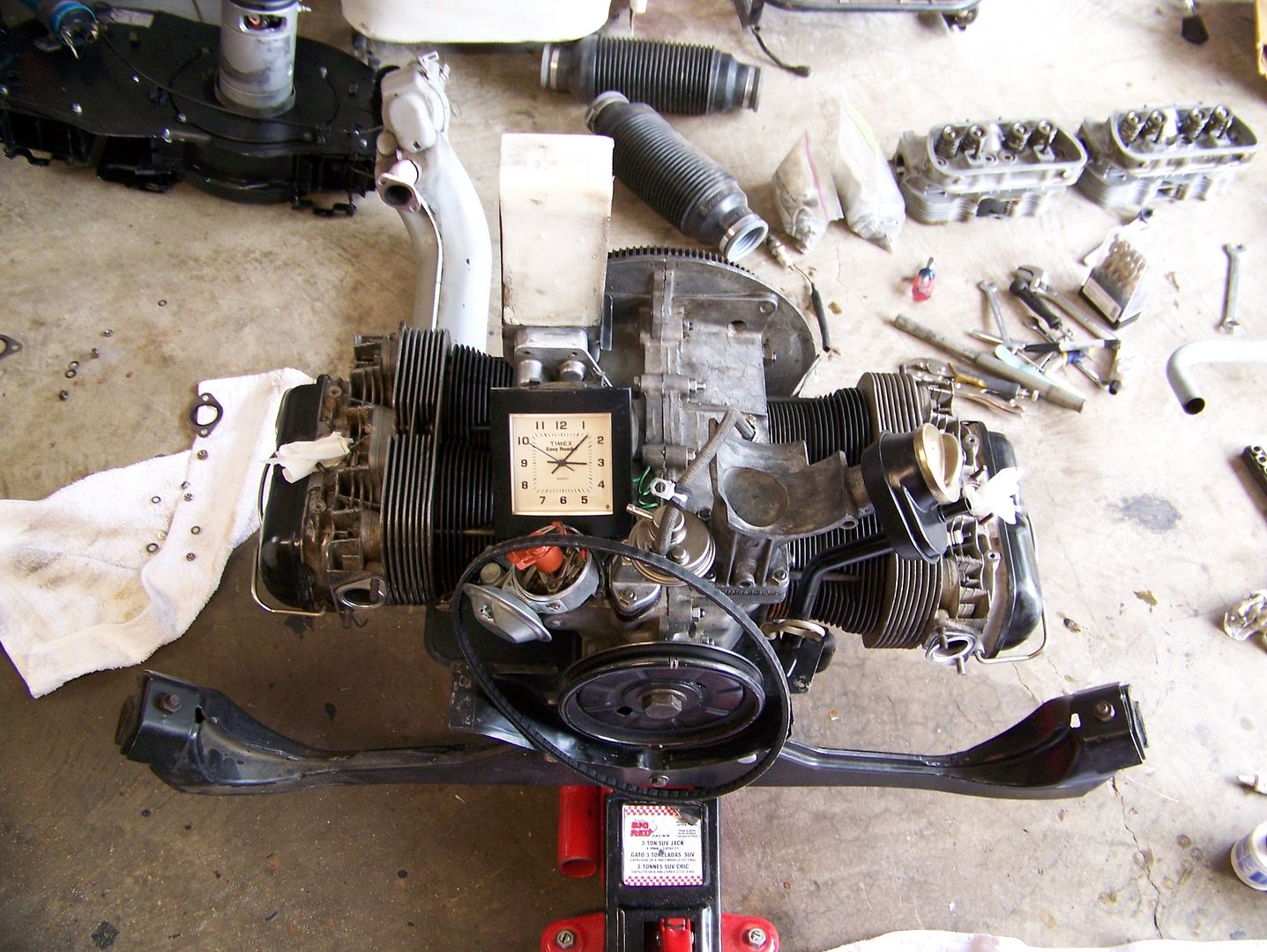

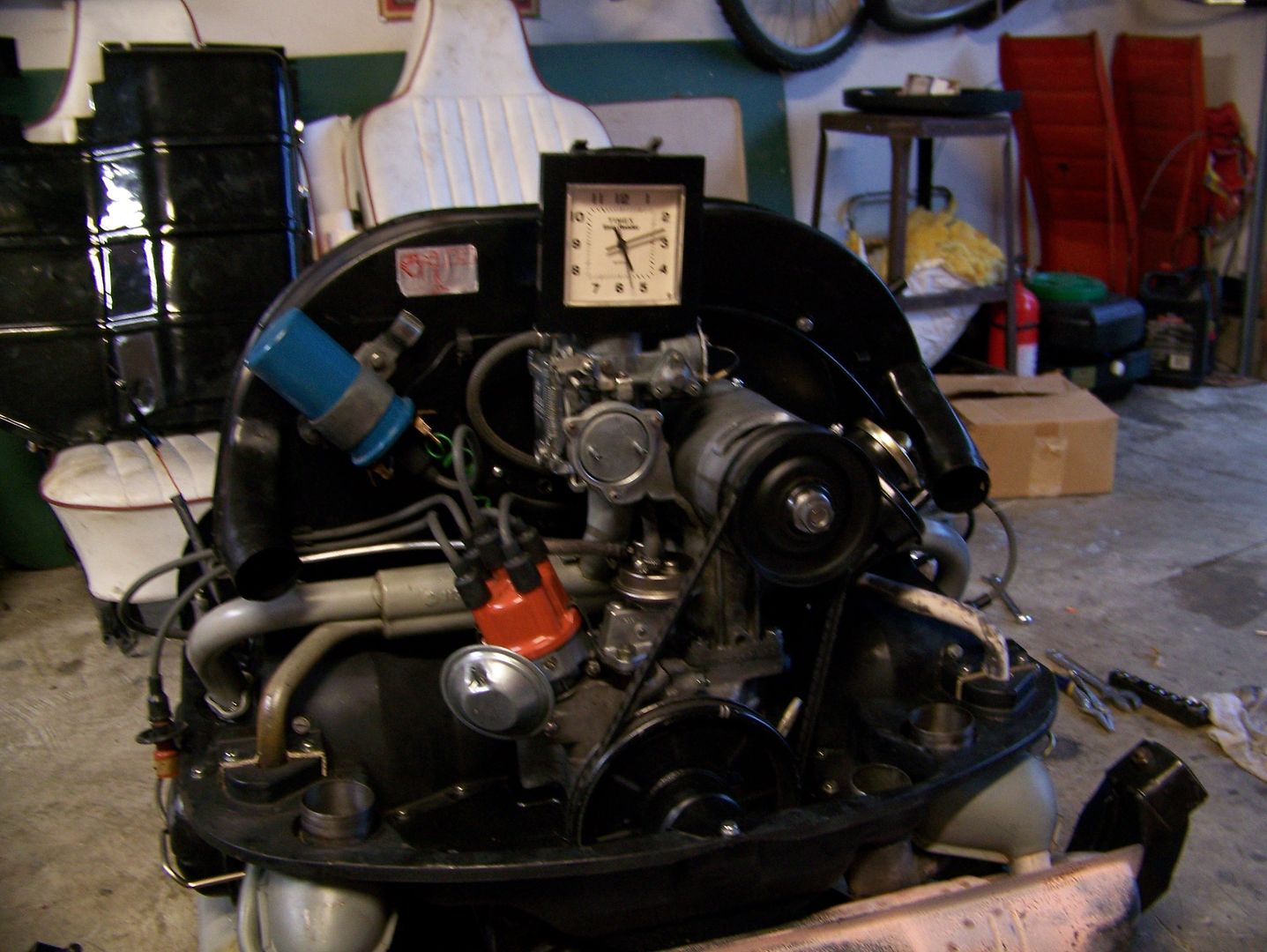

This was a remarkable testament to the incredible toughness of these single port heads. Original valve seat inserts did not move in the cylinder head aluminum, but they apparently were heated to such an extent that the valves were making an impression in the seat contact area. That squiggly little profile line I drew in TX ER 05f was a "mold" of the valve itself! What temperature could possibly ruin the hardening treatment of steel inserts? The little F.I. TRW valves were a strange rust red color without a speck of carbon or anything on them, they were blast-furnace clean, yet they maintained all dimensions.satchmo wrote:Well, I think you knew from the closing gaps on successive valve adjustments that it was either stretching valve stems or sinking valve seats. I'm glad you found the answer in time to avoid a catastrophe.

Tim

Two Used Heads ............................ $ 80.00airkooledchris wrote:total cost for this repair seems to have been relatively low, which is so impressive considering how bad it could have been in the hands of someone that needed to rely on a shop to do it, let alone what *could* have happened had it dropped a valve seat and all the parts that would then be needed to repair.

I look forward to the rest of the story - even after hearing the punchline.

The new sooper-dooper 3-in-1 valve grinding stones that bzoot! knock out the whole 3-angle grind in 7 seconds, may make some hurried harried burned-out machinists ASSUME that all is perfect and they just slap that puppy together.Xelmon wrote:

how can you miss that?

I've been in the machine shop these days doing some good work, and I don't even remember how many times I checked dimensions on stuff that was "Mmm, that's close enough."

Amskeptic wrote:

It is mine now.

Colin