Page 4 of 5

Re: Another Engine Build thread stock type 1 dp

Posted: Sat Mar 31, 2012 7:29 pm

by Amskeptic

ruckman101 wrote:More than one way to skin a cat, as they say.

Thanks everyone for your support during this, my most recent trial of tribulations.

neal

You'll be telling stories on the porch about your VW tribulations some day.

" and then there was the time I ha . . . "

"We have to go now, Neal."

"and the dang bell housing just . . . "

"WE HAVE TO GET GOING NOW, NEAL."

"Whu . . . you have to get who?"

Enjoy your tribulations while the tribulating's good.

Colin

Re: Another Engine Build thread stock type 1 dp

Posted: Mon Apr 02, 2012 10:20 am

by hambone

At least you are diving in and having the perseverance to fix it your damn self and learn from your mistakes. I admire that.

Re: Another Engine Build thread stock type 1 dp

Posted: Mon Apr 02, 2012 2:22 pm

by ruckman101

It isn't rocket science, which is fortunate, because I'm not a rocket scientist.

May the rest flow smoothly,

neal

Re: Another Engine Build thread stock type 1 dp

Posted: Mon Apr 02, 2012 7:14 pm

by ruckman101

Woo Hooo!

Transaxle is back loosely into the car. Tomorrow, snug it all down, repack CVs, get them in, last engine details and then engine in. Getting very close.

neal

Re: Another Engine Build thread stock type 1 dp

Posted: Thu Apr 05, 2012 2:40 pm

by ruckman101

So I thought I would be trick and swap axle positions to essentially give me fresh CVs, but someone beat me to it. Thankfully the wear looks to be essentially the same in both directions, and the first is in much better shape than what were running on the bus.

neal

Re: Another Engine Build thread stock type 1 dp

Posted: Thu Apr 05, 2012 7:42 pm

by ruckman101

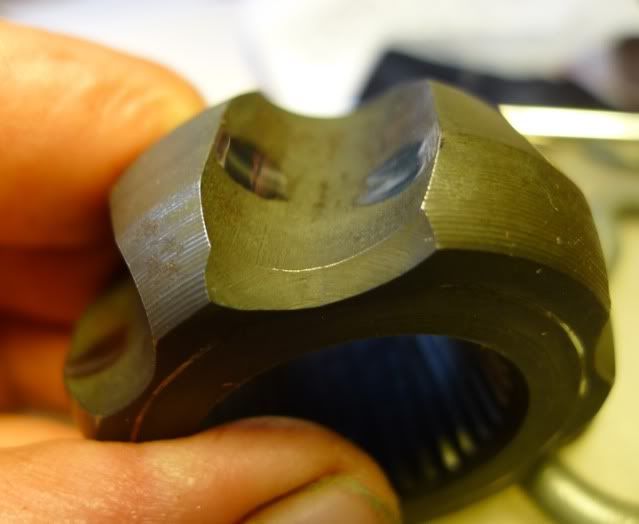

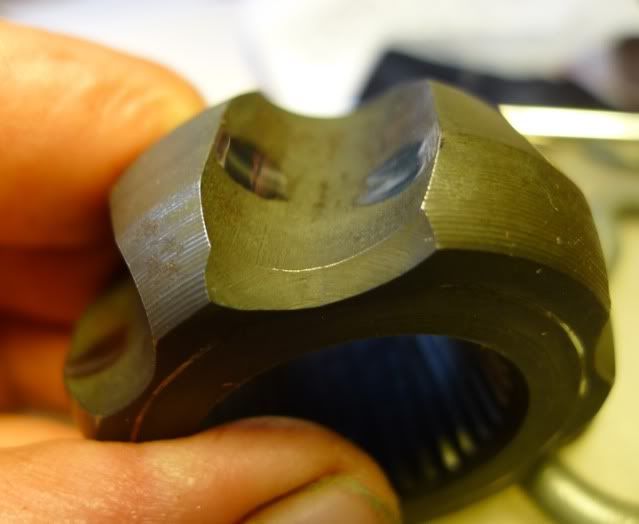

So, with my usual over-thinking, why, what for, etc. re: CVs on Gretchen Ghia.

The cage is smooth on the edge on one side,...

...and has stripes on the edge on the other side.

The inner carrier (?) has a bevel into the splining on one side,...

...and none on the other side.

The outer carrier can only be oriented one direction for the boots to go onto the larger diameter edge.

As for wear, it looks good to me, much better than what I pulled off either bus.

And I had a heck of a time initially getting the inner carrier out of the cage, but then finally it slid out like butter. After I got things cleaned out, I noticed one bearing race had a bevel on the outer edges, and the other five didn't.

You can only get the carrier out of the cage by aligning the beveled race to the edge, otherwise, forget about it.

The beveled splining side of the inner carrier, and the striped edge of the cage were oriented towards the inside of the axle. The flush splining and smooth edge of the cage went towards the wheel or transaxle. I guess that makes sense, in that the retaining clip would want to sit flush against the inner carrier rather than against a beveled edge. This was the orientation of pieces when I pulled the assemblies apart. It seems correct, but if I'm wrong, please let me know.

Someone shout out if my assessment of the wear is folly and I should invest in new CVs.

thanks for indulging me my photo excess,

neal

Another 101 transaxle thread

Posted: Fri Apr 06, 2012 8:28 am

by Amskeptic

ruckman101 wrote:So, with my usual over-thinking,

Stick it together will plenty of grease.

Most importantly, really clean.

The pits and gouges we see are almost always a result of dirty assembly.

Colin

Re: Another 101 transaxle thread

Posted: Fri Apr 06, 2012 8:08 pm

by ruckman101

Well, I have one odd CV out of the bunch. And it was dry. The boot had broken at the axle. Curiously, these boots were clamped to the metal sleeve of the boot with wire. An obvious home touch, not factory engineering. The new ones are one piece, as were the ones that went onto the bus.

The one "different" CV seems to be of inferior quality. What clued me was the lack of a bevel on one of the bearing races like the others had, so it slips out of the cage regardless of which race is oriented to the edge.

And bigger bearings, that have a bit of scuff compared to the others. Nothing major. I think it's still viable.

The cage doesn't seem to have an orientation like the other three, and the bearings popped out much easier than the other three. Otherwise things seem the same, although the odd CV had a dish washer on the axle side, like the ones on the bus, but installed with the dish the correct way. Meatier bearings, thinner inner race. And much more pronounced striations on the race surfaces.

And one more shot, just for fun.

Oops, forgot a shot.

Got to thinking about the engineering numbers, what are the advantages/weaknesses of the ratio of bearing to carriers? Smaller bearings, beefier carriers, smaller bearing footprint, smaller friction profile, less heat? Smaller bearings more vulnerable to being crushed? Vs larger bearings, lighter carriers, more friction, more heat, less mass to dissipate that heat? Can get away with softer grade metals? Less material going into the larger bearing assembly?

I didn't want to take the chance of overly exciting Gypsie, thus I opted for bearings as a descriptor, rather than balls.

neal

Re: Another 101 transaxle thread

Posted: Fri Apr 06, 2012 11:52 pm

by Amskeptic

ruckman101 wrote:

Got to thinking about the engineering numbers, what are the advantages/weaknesses of the ratio of bearing to carriers? Smaller bearings, beefier carriers, smaller bearing footprint, smaller friction profile, less heat? Smaller bearings more vulnerable to being crushed? Vs larger bearings, lighter carriers, more friction, more heat, less mass to dissipate that heat? Can get away with softer grade metals? Less material going into the larger bearing assembly?

I didn't want to take the chance of overly exciting Gypsie, thus I opted for bearings as a descriptor, rather than balls.

neal

Interesting questions, did you say that the larger . . . . spherical bearing . . . had more evidence of scuffing?

Which of the two sizes is VW/Lobro versus aftermarket??

Re: Another 101 transaxle thread

Posted: Sat Apr 07, 2012 2:24 am

by ruckman101

No indication of manufacture on any of them beyond the three that have a VW logo on the outer race.

The numeric 1, and randomly spaced, an 8. But the odd one out? No indication of manufacture. Some numbers. 17-74. And the hyphen is stamped, too. That's it.

Yes the larger bearings have minor pitting, blemishes, scratches or scoring compared to the smaller which gleam pretty in comparison. Remember, the odd CV out was also the only one with a torn boot and dry of grease. I was surprised it didn't look worse than it did. Tactilely, the race surfaces on the odd CV are deeper, but not that far off from the others. All of them have been flipped.

One more thing, the odd CV cage was generic, no obvious difference of one side to the other that the others suggested. The inner race still had a beveled and flush aspect to it like the other three.

I suspect a bad boot in the past and a bad demise for that CV, and a single new replacement some time ago, and at some time the axle position swap and here I am. I'll pack 'em and run 'em.

Those dents in the photo? I didn't do it. Inherited.

neal

Re: Another 101 transaxle thread

Posted: Sat Apr 07, 2012 3:03 am

by ruckman101

Maybe think weakness. Of the two designs, what would be the weak or fail point of each. Smaller bearings or inner race.

neal

Re: Another 101 transaxle thread

Posted: Sat Apr 07, 2012 7:49 am

by Amskeptic

ruckman101 wrote:Maybe think weakness. Of the two designs, what would be the weak or fail point of each. Smaller bearings or inner race.

neal

Neal, it is a toss-up. Now I am confused.

Thicker inner hubs have to have smaller the bearing diameters.

You were saying that the one odd CV had the bigger hubs/smaller balls? or smaller hubs/bigger GYPSIE BALLS?

I personally would think that more metal on the hubs with smaller balls would be stronger, but as you can intuit, surface area load changes very quickly. It comes down to the quality of the metallurgy.

Colin

Re: Another 101 transaxle thread

Posted: Sat Apr 07, 2012 10:36 am

by ruckman101

The odd one out has the bigger ball...bearings and a smaller inner cage.

neal

Re: Another 101 transaxle thread

Posted: Sat Apr 07, 2012 10:45 am

by hambone

We went through this with Sluggo's CVs a couple months ago, except the ball-size was even closer. Took us a while to figure out what was going on.

We were trying to cobble together 1 good CV from a few bad ones...being broke sucks.

It is challenging to keep this technical.

Re: Another 101 transaxle thread

Posted: Sat Apr 07, 2012 11:12 pm

by Amskeptic

hambone wrote:We went through this with Sluggo's CVs a couple months ago, except the ball-size was even closer. Took us a while to figure out what was going on.

We were trying to cobble together 1 good CV from a few bad ones...being broke sucks.

It is challenging to keep this technical.

That is the one thing I will not do is to mix-n-match CVs. The balls and races tracks whatevers are matched to each other to keep the loads as evenly distributed as possible. These are incredibly hard-working parts.

Colin