Page 1 of 2

Dropped valve on type 4 with pics.

Posted: Tue Nov 25, 2014 5:59 pm

by energyturtle

Hello all. Its been kind of quiet around here lately, so here is some food for thought. This is a cv code type 4 I recently acquired. I have nothing in the engine, but some time. When it was brought to me, it was in longblock form plus the fan shroud and flywheel. I rocked the flywheel back and forth, smooth as butter. Later on that night I rotated the flywheel 360 degrees. but it would stop cold 3/4 of the way through the rotation. I rotated CCW, same thing. The heads then came off, and this is what I found. It was stopping when the valve being sideways in the piston would hit the bottom of the plug.

At this point I am looking at new piston, re-ring, Head job including new valves, guides, angle grind etc. and run it. Thoughts please.

Scottie

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 1:36 am

by ruckman101

It sure isn't pretty.

You can certainly do that, it will bide you time ideally. It's a tough call to make, not knowing the prior history of the engine and the integrity of what hasn't failed, and under what conditions would cause the fail it had. If you knew all that, you would be in a better position to gauge how much time it could potentially abide you before a re-build becomes more fiscally prudent than "Git 'er going" band-aid solutions.

neal

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 7:24 am

by energyturtle

That's the beauty of it Neal. This engine is experimental. My personal engine is fine. This is the 6th I've torn into, The bottom ends are Damn near bulletproof. I'm going budget to a new level. This is more to prove resilience than anything. Colin.....where you be?

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 8:30 am

by asiab3

I look forward to an unbiased cost figure of a "budget" T4 build. Everyone touts how much cheaper T1s are, but if your time is free (I hope it is with THAT much gunk you'll be claning off the case,) then this should be fun to watch!

Robbie

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 8:37 am

by Bleyseng

I'd take the P&C off and look at the cam as most hydrolifter engines I have seen that look like that had worn out cams. Many times the worn out cam thru a chain of events causes the valve to snap off. Didn't help that the engine ran freakin hot with that much crap covering it.

Take a look and then decide before dumping just a little cash into parts for a time bomb (GEX style) of just rebuild the sucker.

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 11:56 am

by energyturtle

I am budgeting $300.00. Heat, I agree could be an issue with this one. Time is no issue. I have pulled the lifters one by one, and believe it or not they look amazing, This engine was a complete, sealed longblock that was never left outside. That being said, moisture will not be a factor as I've saw so many times. The valve seats themselves could be an issue, as the valves are not standing tall and proud. This is definently a high mileage, original engine that has never been touched to my knowledge. I am looking forward to the project. Can I get some input of why that valve would snap clean off. I have my theories, but am reserving them for the good of brain storming the community.

Scottie

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 1:49 pm

by Jivermo

What is the end play? If that's not within spec, why waste any time with a patch job, at best. Tear down the whole thing, and do it up right for a spare engine. Is there any GEX sticker, or markings up on the top center of the case above the flywheel? There is too much valuable time and labor involved to install a questionable engine in a bus.

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 3:40 pm

by energyturtle

.00457 end play. I have 2 perfectly good brand new build engines. One of which is installed. This is not a GEX build, but a bone stock, Cv code 2 Litre Hydraulic. I must say no to a split case tear down at this time. Reason being, my first full build cost 1500.00 in parts and machine work. I have nothing in this engine. Valuable time and labor is in the eye of the beholder. What is our philosophy here? What have we learned? I speak for myself when saying this, As we replace OG parts with aftermarket junk we are getting one step closer to extinction. We know of the Roadwarrior story. All the miles, the abuse. This engine wants another chance. I asked it what it wanted and it told me. Look a the road grime. This thing has been ridden hard....REAL HARD. The very nature of its failure tells me enough. I have never saw a valve stuck in a piston like that without going through, The engine stopped cold when this happened, based on the rotation of TDC for that piston, the angle of the valve was perfectly aligned with the bottom of the plug that caused it to seize. When this engine was in the bus it would have gave the ILLUSION of being locked up tight. This is pure speculation, but I bet this bus was took to a shop that diagnosed a locked up engine and instead of fixing it, the owner opted for the remanufactured route for cost efficency purposes.....hence that bus like so many others probably has a GEX POS in it now. The way I look at it I got the good one. OG, german air-cooled. Being a CV code 80-83 vanagon, I truly have the last factory german air-cooled motor made for importation into the U.S. I am gonna let it be what it was intended. Rock solid, legendary reliability other than the occasional valve issue.........Stay tuned.

Scottie

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 6:01 pm

by Bleyseng

I have a 914 2.0L with the same problem, a broken off intake valve stuck in the piston. Happened after driving it hard and then idling it according to the PO. Mine was run really lean judging by the spark plugs so really hot.....

It will probably run fine for a while if you just fix a few of it's issues but for a long term engine check the cam condition.

Re: Dropped valve on type 4 with pics.

Posted: Wed Nov 26, 2014 6:58 pm

by energyturtle

For sure man. If the lobes look as good as the lifters I'll be happy. Looks like it had plenty of oil during its first life. Its all over it. The rockers and stands as well as inside the valve covers are still shiny. The valve spring that failed has major carbon build up. I suspect the guide is shot allowing back pressure during the compression stroke. Lifters are shiny like new, no heat or stress in the pistons or the contact point.

Re: Dropped valve on type 4 with pics.

Posted: Thu Nov 27, 2014 9:51 am

by jcbrock

energyturtle wrote:.00457 end play.

Scottie

Serious question - how do you measure the endplay to 70 microinches? That's really small, like 17 angstroms. I feel good if I can get the valve clearance to 0.006".

Re: Dropped valve on type 4 with pics.

Posted: Thu Nov 27, 2014 2:28 pm

by energyturtle

My friend is a machinist his digital Indicator goes that far.....let's just say .004 to clear things up.

Scottie

Re: Dropped valve on type 4 with pics.

Posted: Thu Nov 27, 2014 2:38 pm

by energyturtle

ummmm... Had a thought. I bet he had the digital indicator in the wrong unit of measurement. Back to the drawing board.

Scottie

Re: Dropped valve on type 4 with pics.

Posted: Thu Nov 27, 2014 3:59 pm

by jcbrock

It's worth double-checking. Not trying to be a smarta** at all, but when I saw it I wondered if it was right. Gas engine work scares me, and if I have to do stuff to a hundredth of a thosandth, nope, not doing it - I'll stick to my steam engines thank you!

Re: Dropped valve on type 4 with pics.

Posted: Thu Nov 27, 2014 8:03 pm

by Amskeptic

energyturtle wrote:

ummmm... Had a thought. I bet he had the digital indicator in the wrong unit of measurement. Back to the drawing board.

Scottie

I say, "have fun." Yes, it is a good idea to do forensics as to the why on the valve failure, but a used un-mangled original CV engine is a great foundation to do a quik-n-dirty $300.00 slap-it-together and find out you have a real sweetheart.

BUT . . .

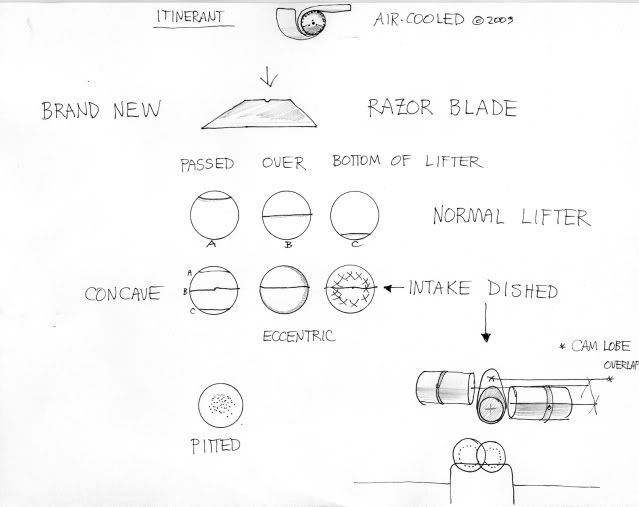

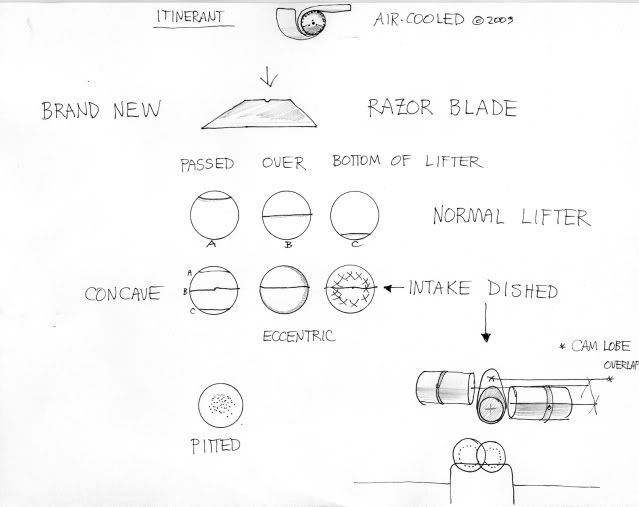

You have to have an alert eye. The head must be carefully inspected. If the valve guide is damaged or worn, you have to grind the seats after the new guides, can the seats take a grind and still have the correct margins and widths? You look at each piston and cylinder and gauge the amount of oil sitting at the bottom of the cylinder, you carefully put the piston to the bottom of the cylinder and check the condition of the walls, if the lifters look good, get a machinist's straight edge and look for a little convex on the bottom of the lifter. They can look perfectly smooth, yes, but they could be worn flat. Can you get a fingernail to the intake cam lobes? If your fingernail catches, that cam is worn through the hardening treatment:

You *can* overlook a bunch of things if you are not looking for a 150,000 mile engine.

BUT

You can overlook a bunch of things that make it a 300 mile engine, too . . .

Colin