Page 4 of 4

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sun Jul 13, 2014 11:18 am

by Jivermo

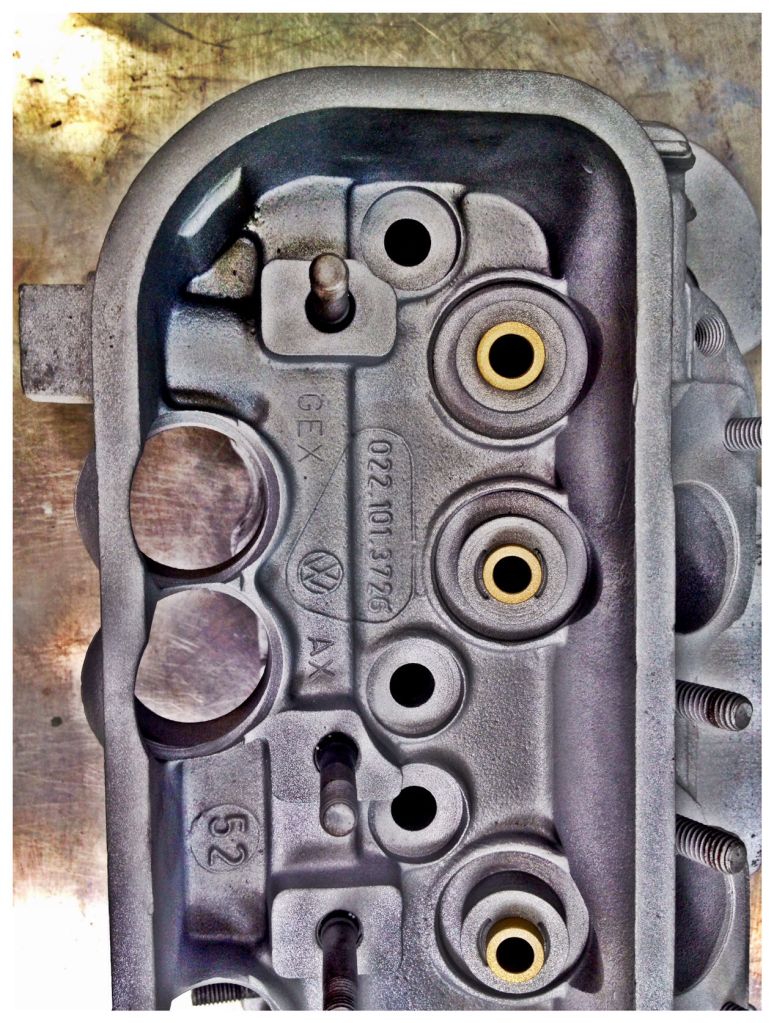

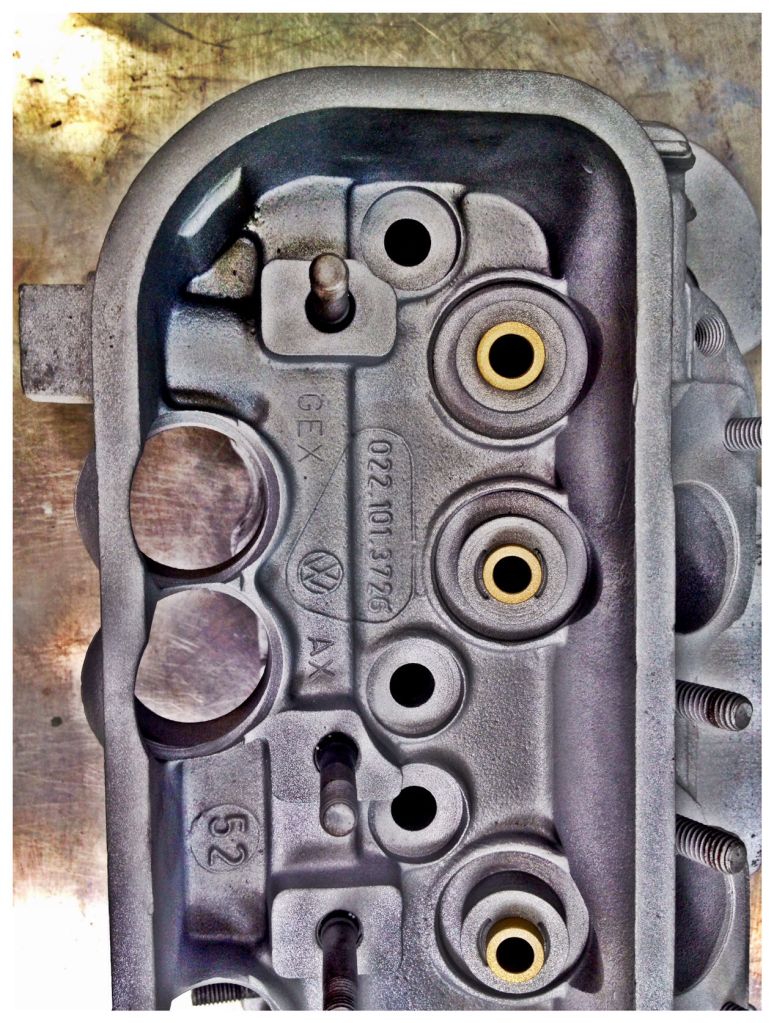

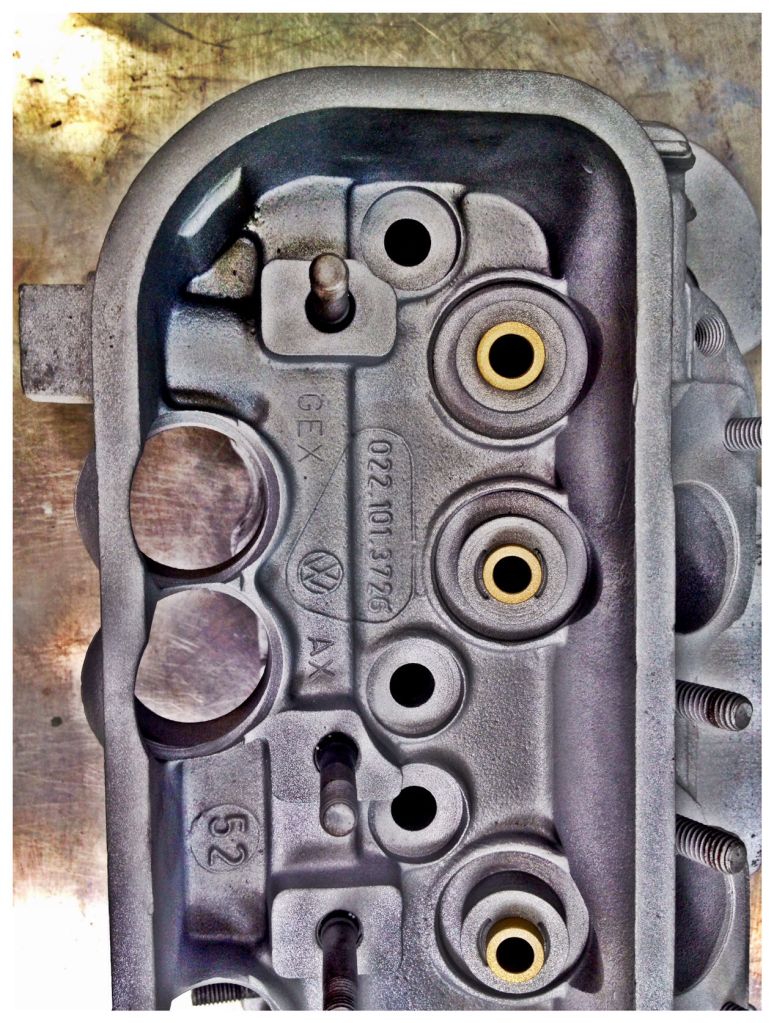

My beautiful GEX heads.

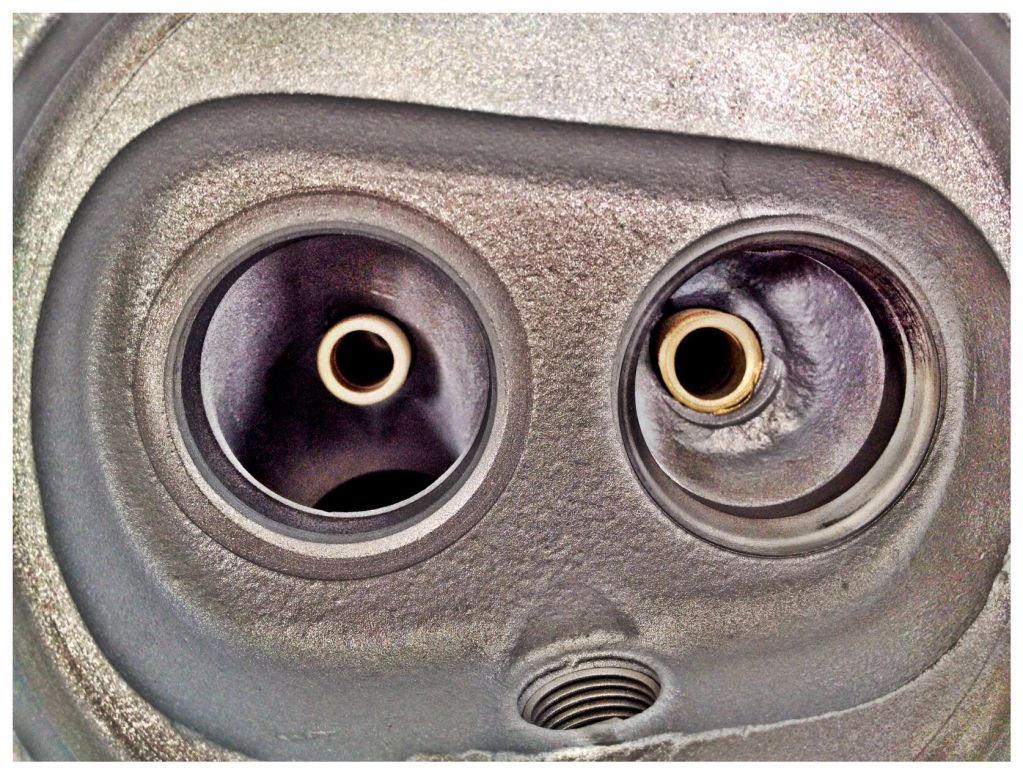

My son in law, David, took my heads over to his shop, and cleaned and media blasted them. Things are revealed. Now, I'll not pretend that I know what I'm looking at here, but I do know a crack when I see one. By the way, I do have new heads on order with Adrian, but I'd like to learn what is up with these heads. Here is the readily apparent crack:

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sun Jul 13, 2014 11:29 am

by Jivermo

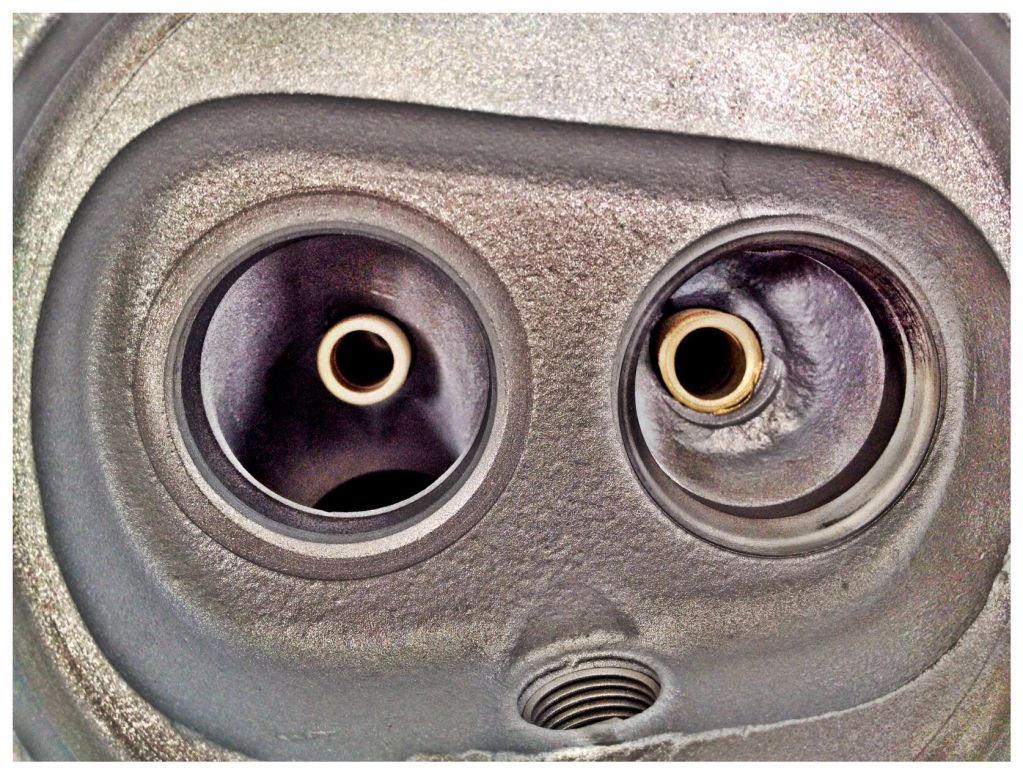

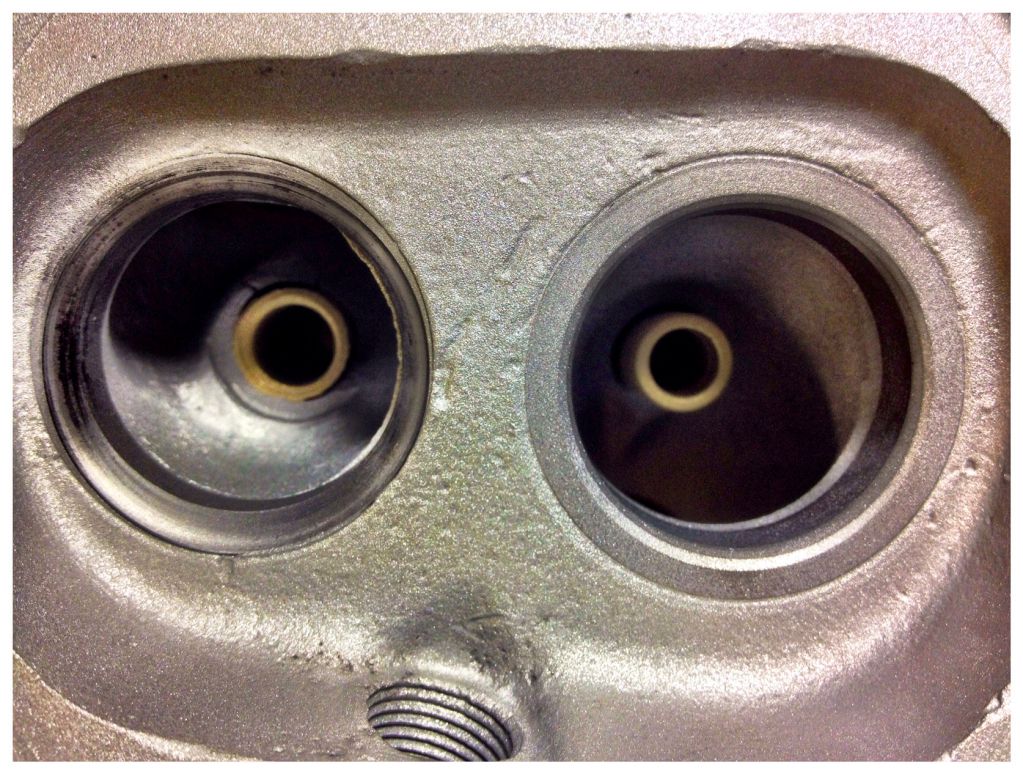

Here is the other head, with another developing crack, I think.

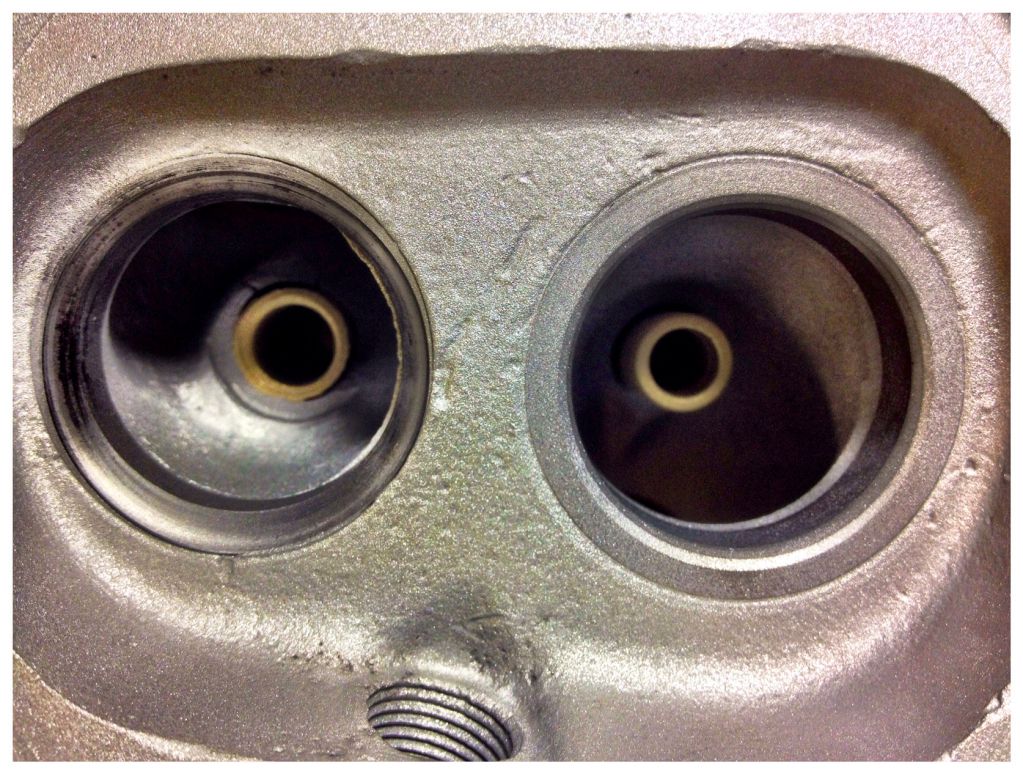

And here is a "good" section:

I would appreciate all the feedback I can get on the condition of these heads. Is there a three way grind on some of these seats? Is the seat in the last pic beginning to recess? I want to learn what to look for when I look at a head. Thank you!

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sun Jul 13, 2014 11:31 am

by Jivermo

I guess I have a couple of new paperweights for my desk, eh? Or canoe anchors. Oh, and...when I called this an "adventure", I really meant it.

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sun Jul 13, 2014 2:11 pm

by Bleyseng

What's with the exhaust seats???

I see GEX stamped so maybe they can be saved from a fate worst than death with a proper rebuild.

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sun Jul 13, 2014 2:34 pm

by Jivermo

And here I've been thinking that GEX was the fate worse than death. Seriously, everything I read advises against reusing heads on a rebuild. A false economy, I gather.

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Mon Jul 14, 2014 4:55 am

by Bleyseng

The aluminum gets soft under the seats from heat cycling so the seats can have a problem staying in. Cracks have to be rewelded so rebuilds doing it right can be expensive so buying new heads is the best option. HAM doesn't rebuild bus heads but HFM does if they pass their inspection.

I went with new AMC heads on my rebuild for peace of mind.

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Mon Jul 14, 2014 5:01 am

by Jivermo

Yes...peace of mind. I believe that there is a direct correlation between the thought of that head crack barging into the mind, and the remoteness of the bus location as it is being driven with the reworked head. I'll go for new AMC, too.

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sat Jul 19, 2014 5:08 am

by Jivermo

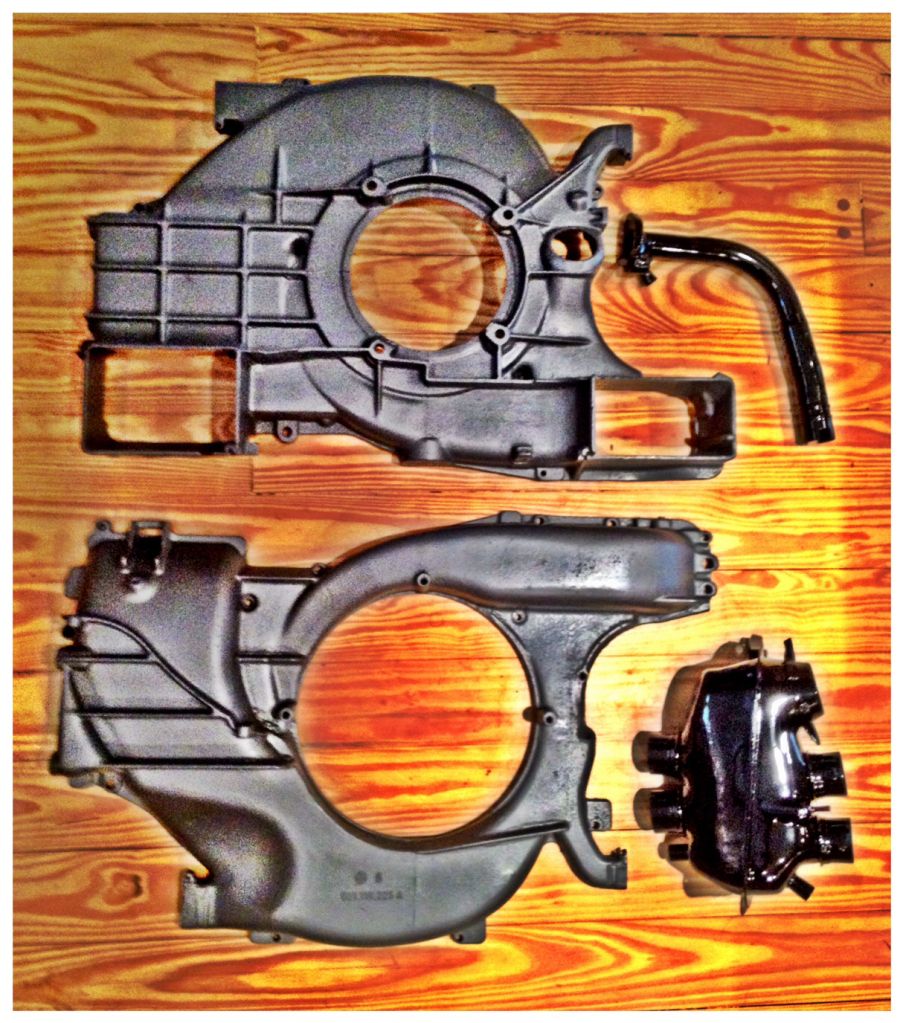

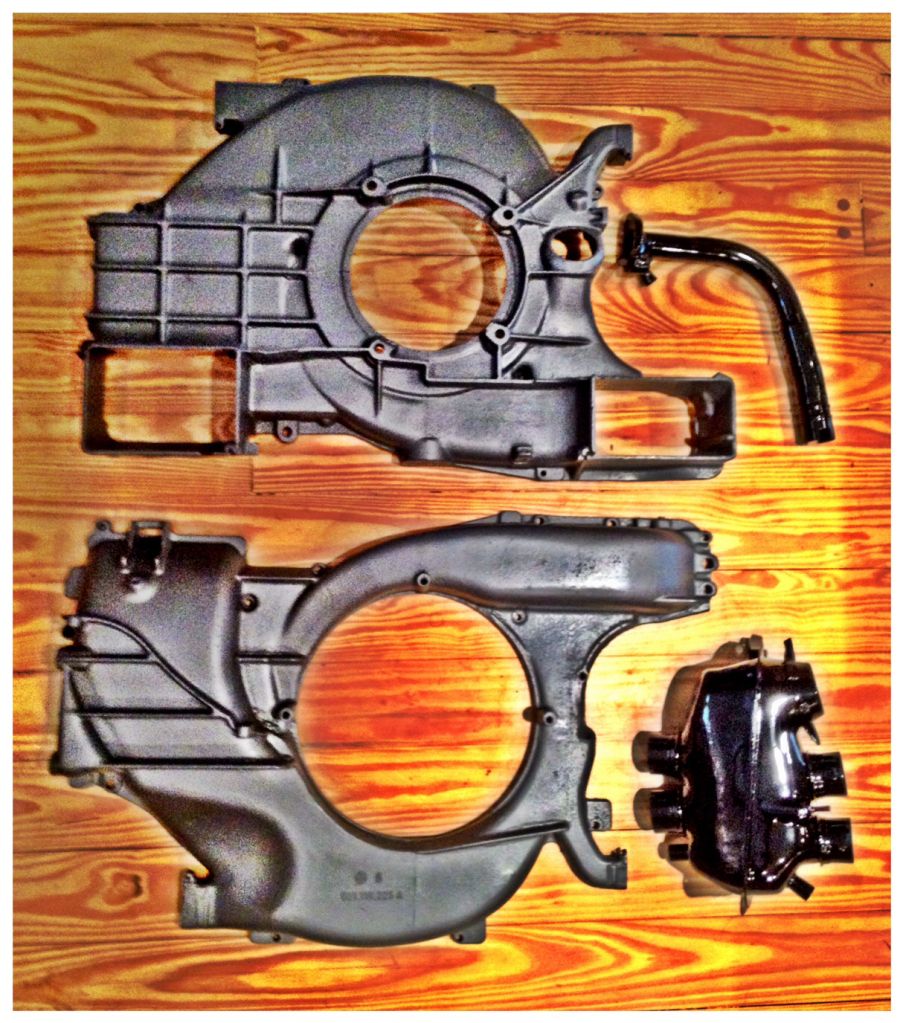

Parts are back from Awesome Powder Coat. Clark there does nice work, and is a pleasure to deal with.

Re: The Irreverent Air Cooled Rebuild Adventure.

Posted: Sat Jul 19, 2014 10:45 pm

by Amskeptic

Jivermo wrote:Yes...peace of mind. I believe that there is a direct correlation between the thought of that head crack barging into the mind, and the remoteness of the bus location as it is being driven with the reworked head. I'll go for new AMC, too.

I had worse cracks on the Road Warrior's heads and in the exhaust ports. I cannot discern what is going on with the exhaust seats because it looks like everything was willy-nilly blasted.

Are the exhaust seats themselves flush with the head ceiling (can you tell the difference between the surrounding aluminum and the seat steel, or did the blasting make everything look the same?) or is the steel noticeably lower than the surrounding aluminum?

If you have an exhaust valve laying around, stick it in an exhaust guide and see what the contact area is on the seat. It should be not less than 2mm and not more than 3mm. Does the valve stand proud of the seat/combustion chamber ceiling, or does it appear to be slightly "counter-sunk".

Airkooledchris and I discovered today that the AMC heads have too sharp of an edge where the pushrod tubes fit into their holes. I gave Chris an Itinerant Scissorhands lesson in scraping a nice EZ radius to help the new seals tuck into position as the push rod tube is driven home.

Long ago I discovered that the AMC heads are machined too smooth for the cork valve cover gaskets. Blasting that machined surface would help our usual cork gaskets/grease to provide a leak-free fit.

Colin