Page 2 of 2

Re: Wiper Assembly Refresh

Posted: Thu Oct 06, 2016 8:19 pm

by chachi

yeah, i've got the post vice gripped up into the shaft so i can get as much of the groove exposed as possible. i'm assuming you want the C clips to face different directions, kind of like piston rings, but get one on and the second one wants to bend more than it wants to slip on.

Re: Wiper Assembly Refresh

Posted: Sat Oct 08, 2016 7:36 am

by Amskeptic

chachi wrote:yeah, i've got the post vice gripped up into the shaft so i can get as much of the groove exposed as possible. i'm assuming you want the C clips to face different directions, kind of like piston rings, but get one on and the second one wants to bend more than it wants to slip on.

Do you have the companion shaft assembled so you can check dimensions? Is there an errant little washer mucking up the works? I have seen too many wiper shafts that move up and down sloppily, so yours is an outlier.

Colin

Re: Wiper Assembly Refresh

Posted: Mon Oct 17, 2016 5:39 pm

by chachi

looks right, you're thinking the errant clip might just be in the shaft somewhere? i lubed the crap out of the groove and the clip and finally got it "on"...sort of. pinched and squeezed and pried and it was on there. but rotating the shaft just worked that clip right off. i reassembled without the second clip and there was no slop so i just went with it. managed to drop a bushing into the hollow between the out and insides under the windshield channel but after buying another it looks AIC-ok. didn't know what else to do to get it on there.

Re: Wiper Assembly Refresh

Posted: Sun Oct 23, 2016 5:46 am

by chachi

surprised to see new wiper arms come un-splined...?

Re: Wiper Assembly Refresh

Posted: Sun Oct 23, 2016 9:34 am

by asiab3

Iiiiiiinteresting. I wonder if they're such soft metal the splines will etch themselves in at first tightening? Or I wonder if the manufacturers have such soft spines that they've given up.

Though I'm temped to agree with GoWesty's eight foot/pound rule for tightening. I would NOT want to strip the threads.

Robbie

Re: Wiper Assembly Refresh

Posted: Sun Oct 23, 2016 4:16 pm

by Amskeptic

chachi wrote:surprised to see new wiper arms come un-splined...?

That is how they come! It is soft potmetal! You get to adjust the arms to exacting perfection! You tighten the nuts down to factory-specified torque and you re-check after the first use! Then they will be Kustom-Splined.

Colin

Re: Wiper Assembly Refresh

Posted: Mon Oct 24, 2016 10:19 am

by chachi

yeah i removed one after tightening it down and it did appear to spline it. interesting. kind of surprised my old ones lasted as long as they did, neglected as they were.

thanks for this tune up thread and your help!

Re: Wiper Assembly Refresh

Posted: Fri Sep 08, 2017 5:52 am

by furgo

Six years after, this is still a very useful post, thanks!

As soon as I fix some more pressing engine issues, I'm planning to go through this procedure, as my windshield wipers currently move in slow motion. To complement the post, I thought I'd add a picture of the Phillips screw that holds the glovebox as mentioned on Step 1.

For easy finding, it sits to the left of the

silver socket.

Picture taken looking from behind of the glovebox compartment. Left: silver socket, next to it, the glovebox strap screw

Re: Wiper Assembly Refresh

Posted: Fri Sep 08, 2017 5:51 pm

by Amskeptic

furgo wrote: ↑Fri Sep 08, 2017 5:52 am

Six years after, this is still a very useful post, thanks!

As soon as I fix some more pressing engine issues, I'm planning to go through this procedure, as my windshield wipers currently move in slow motion. To complement the post, I thought I'd add a picture of the Phillips screw that holds the glovebox as mentioned on Step 1.

For easy finding, it sits to the left of the

silver socket.

IMG_20170908_095606.jpg

Picture taken looking from behind of the glovebox compartment. Left: silver socket, next to it, the glovebox strap screw

Watch out for that silver socket . . . it is live.

All three of my VW buses have lively wipers, but they need exercise to keep the magnets happy. Also, it is more apparent to me after all of these years and buses, that the shafts need lubrication through the threaded sleeves. Automatic transmission oil and a little engine oil seems to work well as a penetrant and a decent lubricant.

Colin

Re: Wiper Assembly Refresh

Posted: Mon Sep 11, 2017 9:23 am

by sgkent

as my windshield wipers currently move in slow motion.

often a sign that the plastic gear inside the motor is cracked.

https://www.thesamba.com/vw/classifieds ... id=1720906

Re: Wiper Assembly Refresh

Posted: Mon Sep 11, 2017 10:40 pm

by Amskeptic

sgkent wrote: ↑Mon Sep 11, 2017 9:23 am

as my windshield wipers currently move in slow motion.

often a sign that the plastic gear inside the motor is cracked.

How is that, Steve? I can't visualize a crack causing slow operation.

Colin

Re: Wiper Assembly Refresh

Posted: Tue Sep 12, 2017 4:15 am

by furgo

Amskeptic wrote: ↑Mon Sep 11, 2017 10:40 pm

sgkent wrote: ↑Mon Sep 11, 2017 9:23 am

as my windshield wipers currently move in slow motion.

often a sign that the plastic gear inside the motor is cracked.

How is that, Steve? I can't visualize a crack causing slow operation.

Colin

Thanks for the heads up on the plastic gear. I too asked myself the same question as Colin, as well as how can this be checked without taking the motor apart.

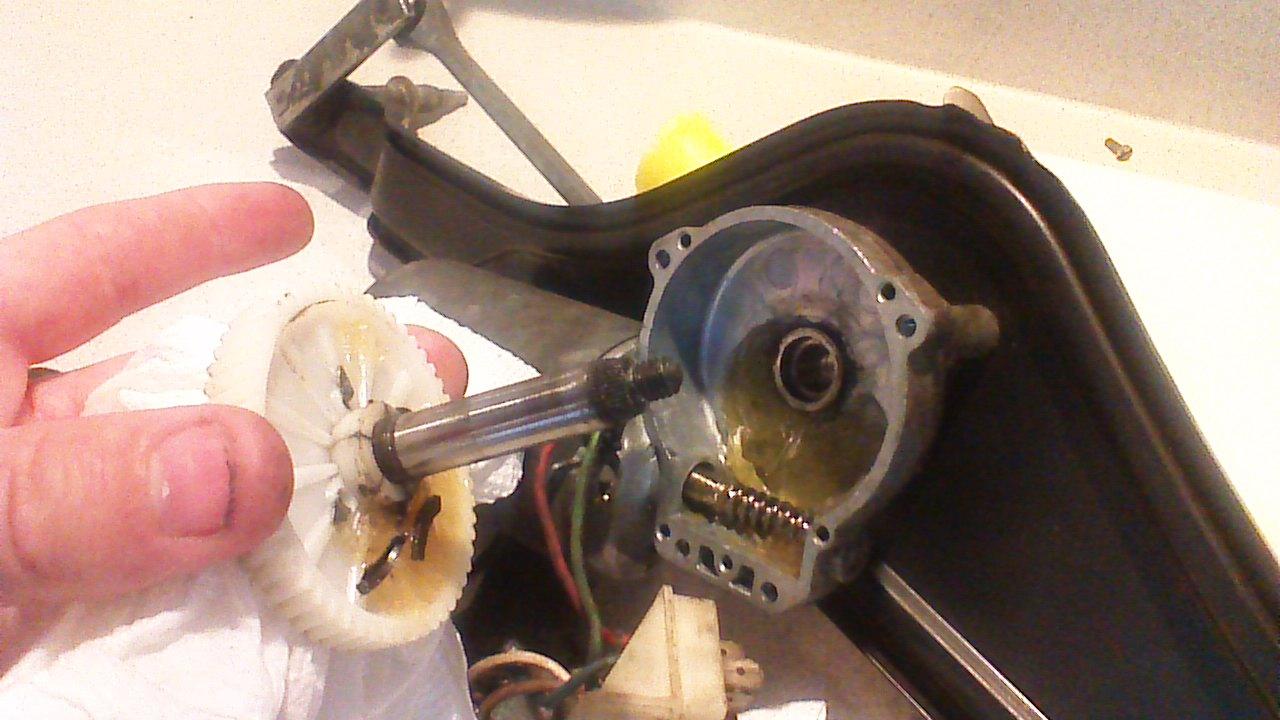

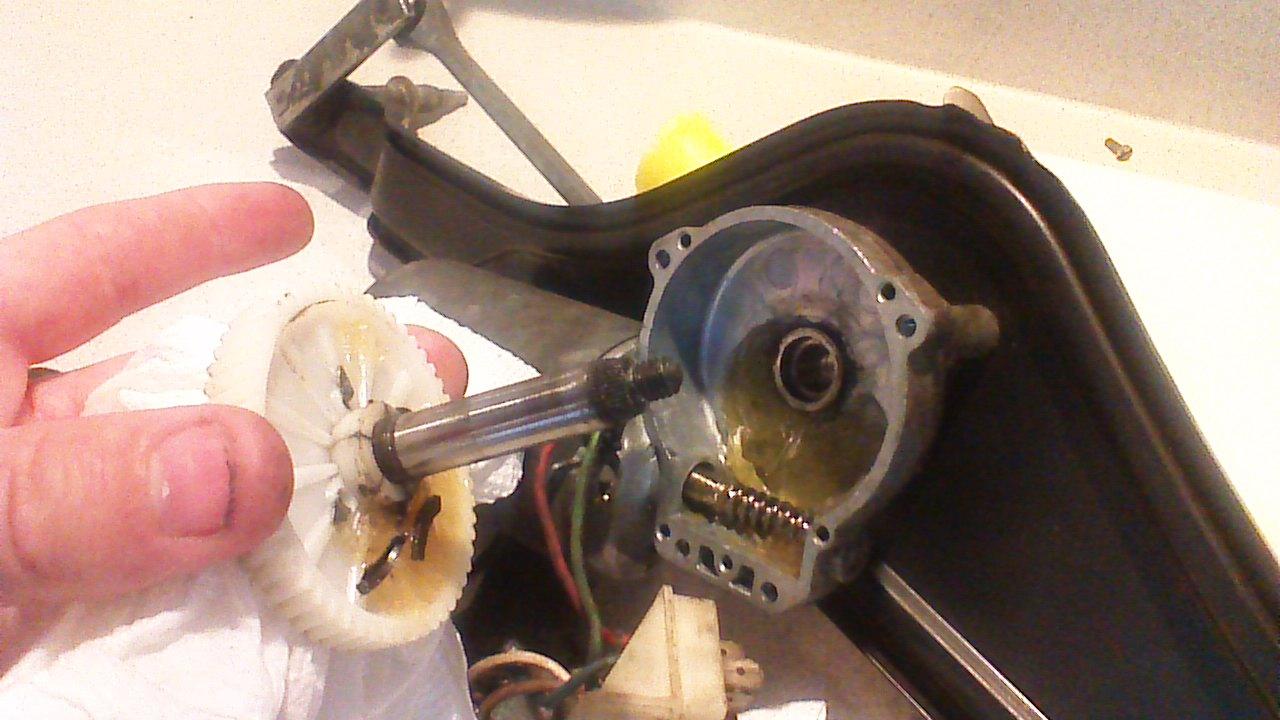

In any case, here are some more pictures I took a few days ago to complement step 2:

Heater ducts block removal of wiper motor assembly (view from the radio opening)

Late bus ventilation register viewed from the top:

Removing a late bus left ventilation register (view from the bottom). Be careful not to damage the mono speaker if you've still got it in there.

Re: Wiper Assembly Refresh

Posted: Tue Sep 12, 2017 8:10 am

by sgkent

How is that, Steve? I can't visualize a crack causing slow operation.

Colin

I too asked myself the same question as Colin, as well as how can this be checked without taking the motor apart.

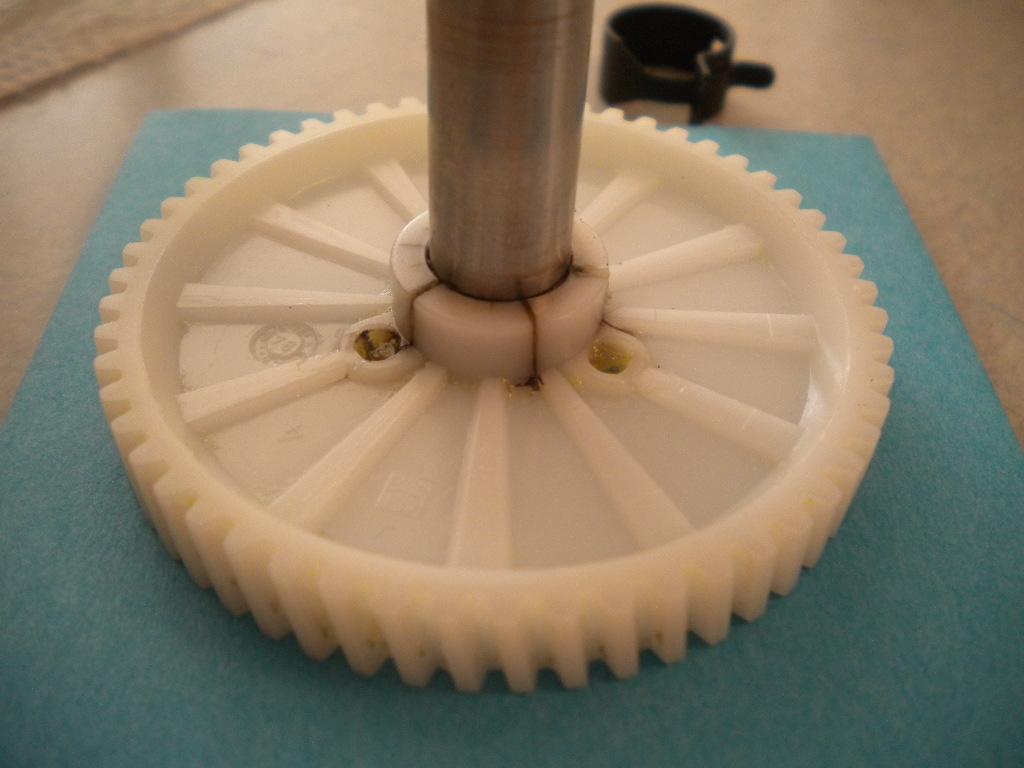

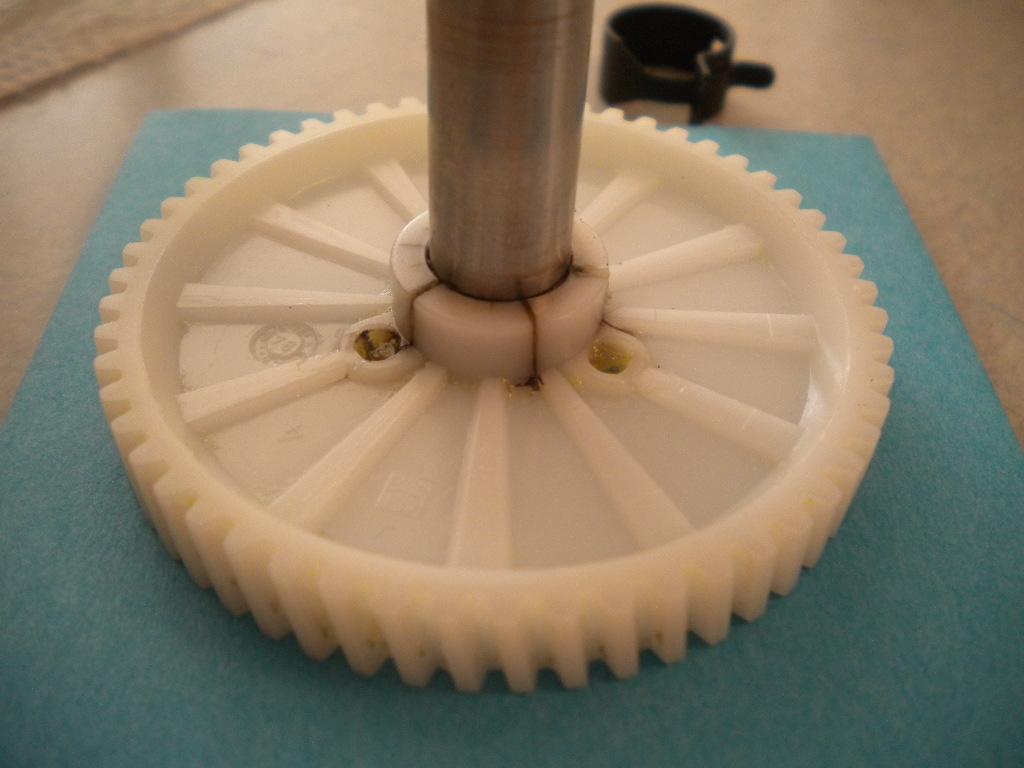

because when the gear inside the motor cracks the center shaft slips in the plastic so the gear turns slower and slower. The wipers will slow and then eventually stop when the plastic spines are eaten away. The most common way to test is raise the wipers and turn them on (if the radio antenna is out of the way. They will go at a normal speed because there is no load. Put them on a windshield with some water or windex and they will go slow or stop as the spindle slips in the plastic gear.

see the cracks at the spindle. Photos from TS

The fix since new gears are not available and epoxies don't hold