sped372 wrote: ↑Tue Jan 30, 2018 12:04 pm

Yes, I plan to...

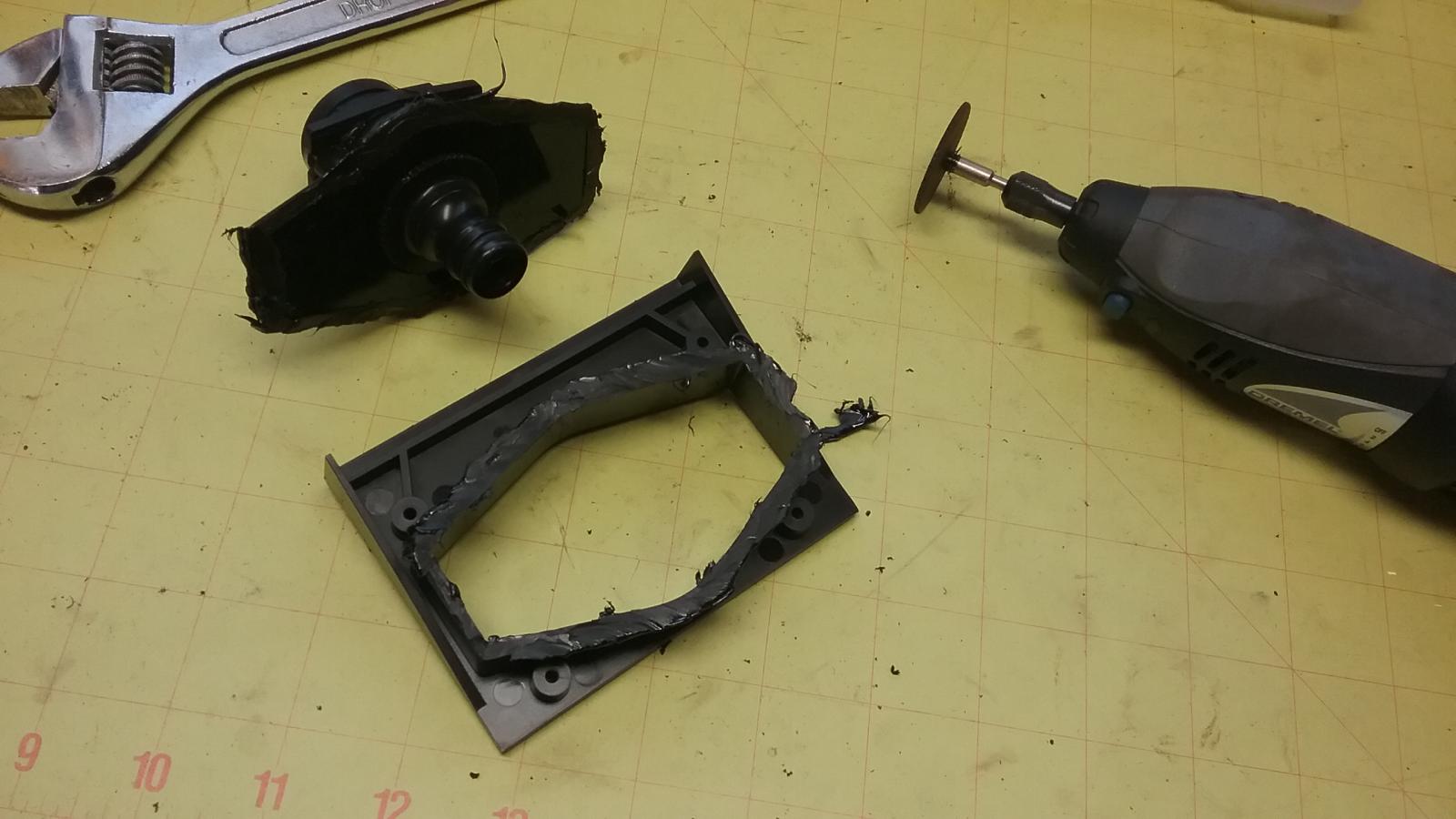

If the cracks weren't there brand-new it could have been a creep-related failure or any other stackup of environmental conditions that led to the cracks forming later.

I remember your professional job description, and I must tell you here that my eyebrow is cocked and I am . . . smirking lightly (think: modern FSP dryer fan, remember that conversation?).

AND I tell people working with aftermarket @*^&! plastic that the most likely cause of a crack such as yours is all of us forgetting that there are forces that occur after we have left the job site. Mechanical stress and thermal stress must be taken into account.

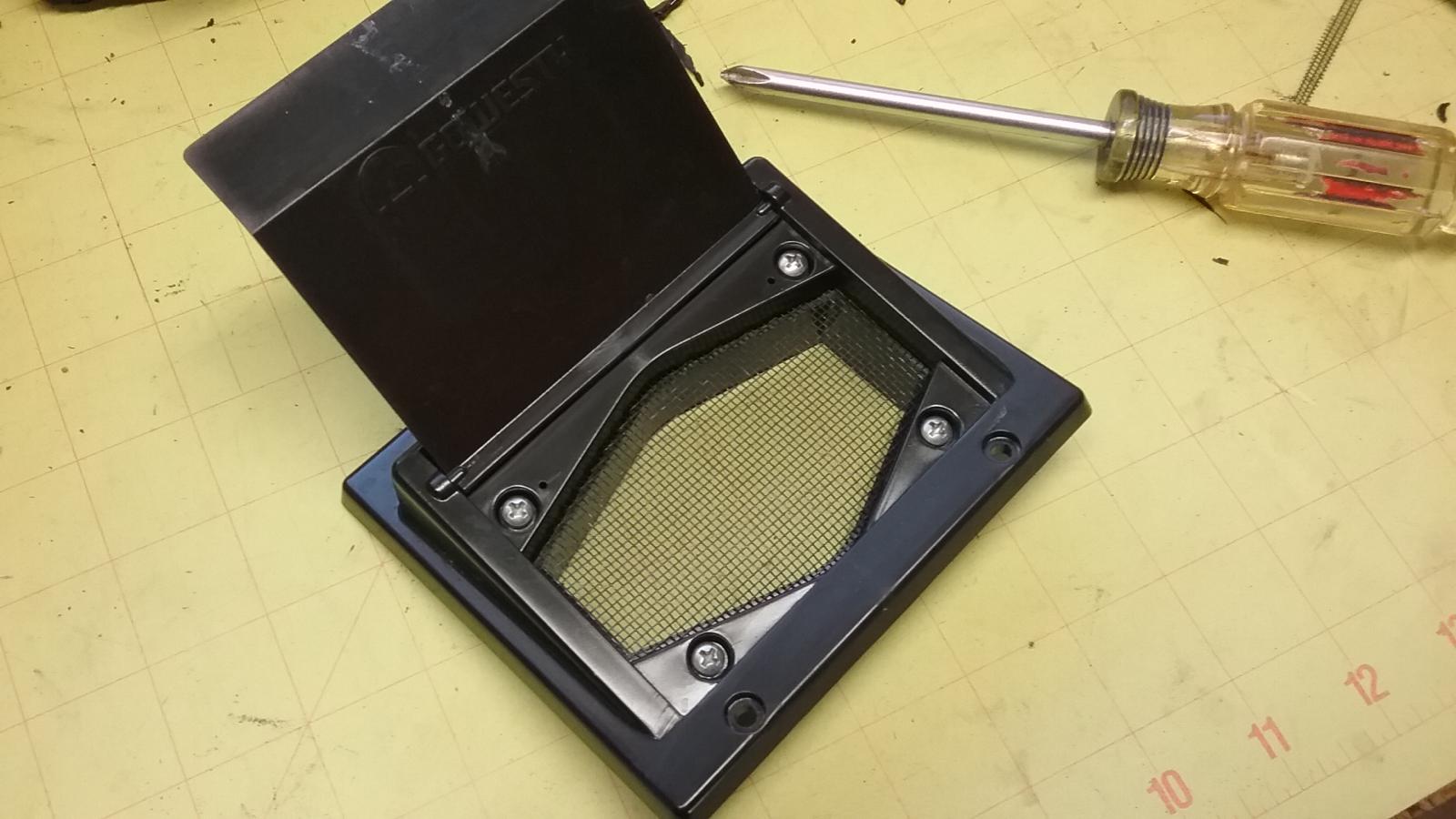

In your case, those big honking coarse self-tapping screws in a slightly too-small bore may have very well overwhelmed the walls at first tapping/tightening. My question to you, knowing your experience with these very sorts of assemblies, is do the self-tapping screws have a taper all the way up the shank? Would that cause a two-fold stress failure from over-tightening? a) the diameter of the screw breaches the wall, and b) due to the tightness of the assembly, can simple heating in the sun cause an expansion that cracks the flanges/walls?

I have a thoroughly explicated procedure with my customers when we install turn signal and taillight lenses.

DO NOT OVERTIGHTEN yes, but also:

a) press the housing with your palm to seat the gasket

b) bring up the screws (in a cross pattern if necessary) to sort-of snug

c) rotate the screws a c-hair counter-clockwise

This for every plastic assembly of every car or appliance I come across.

Thoughts, observations, engineering analyses, welcome.

Colin

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles