Page 1 of 1

Fuse box corrosion

Posted: Sun Jan 06, 2013 11:26 am

by satchmo

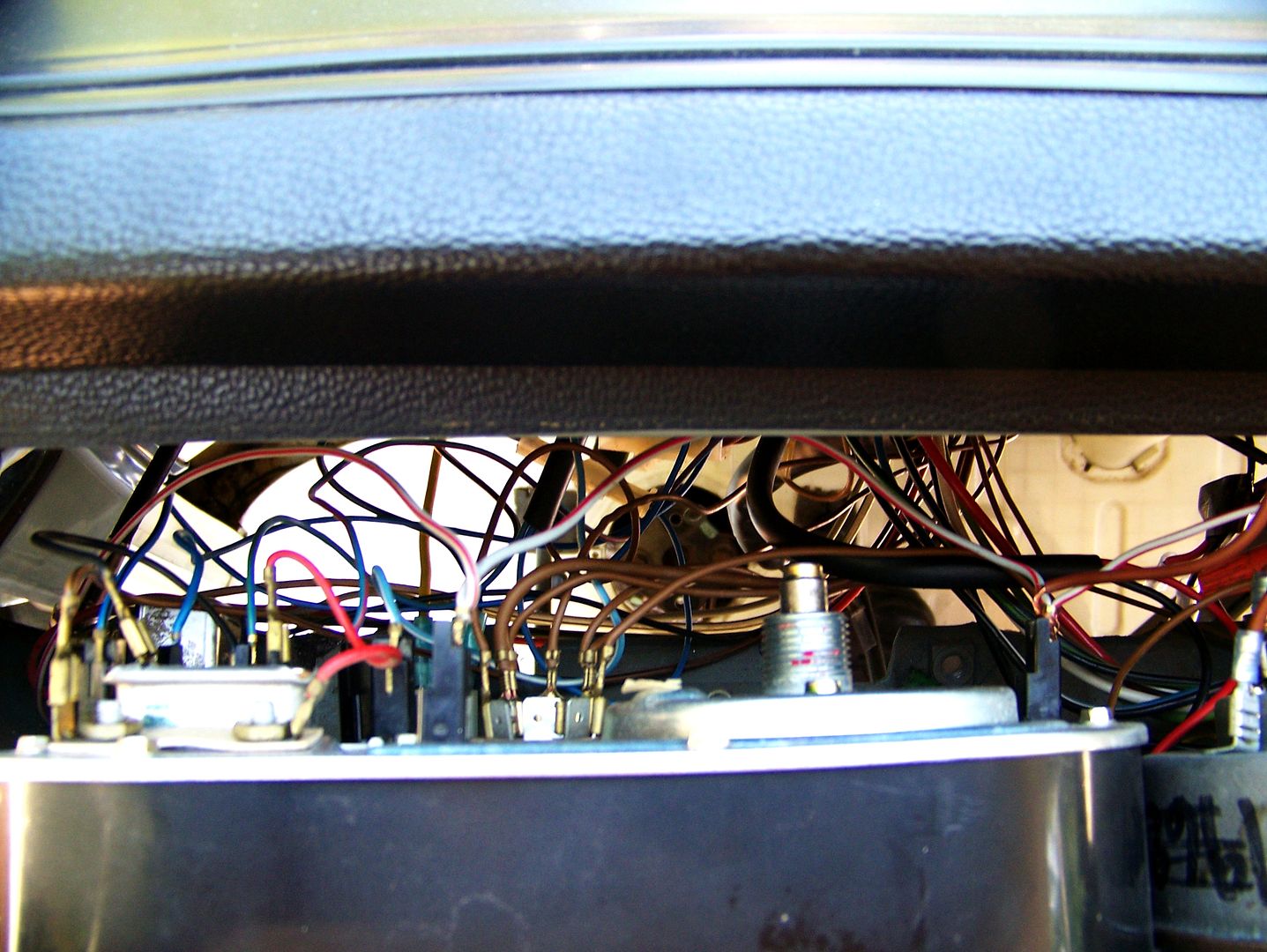

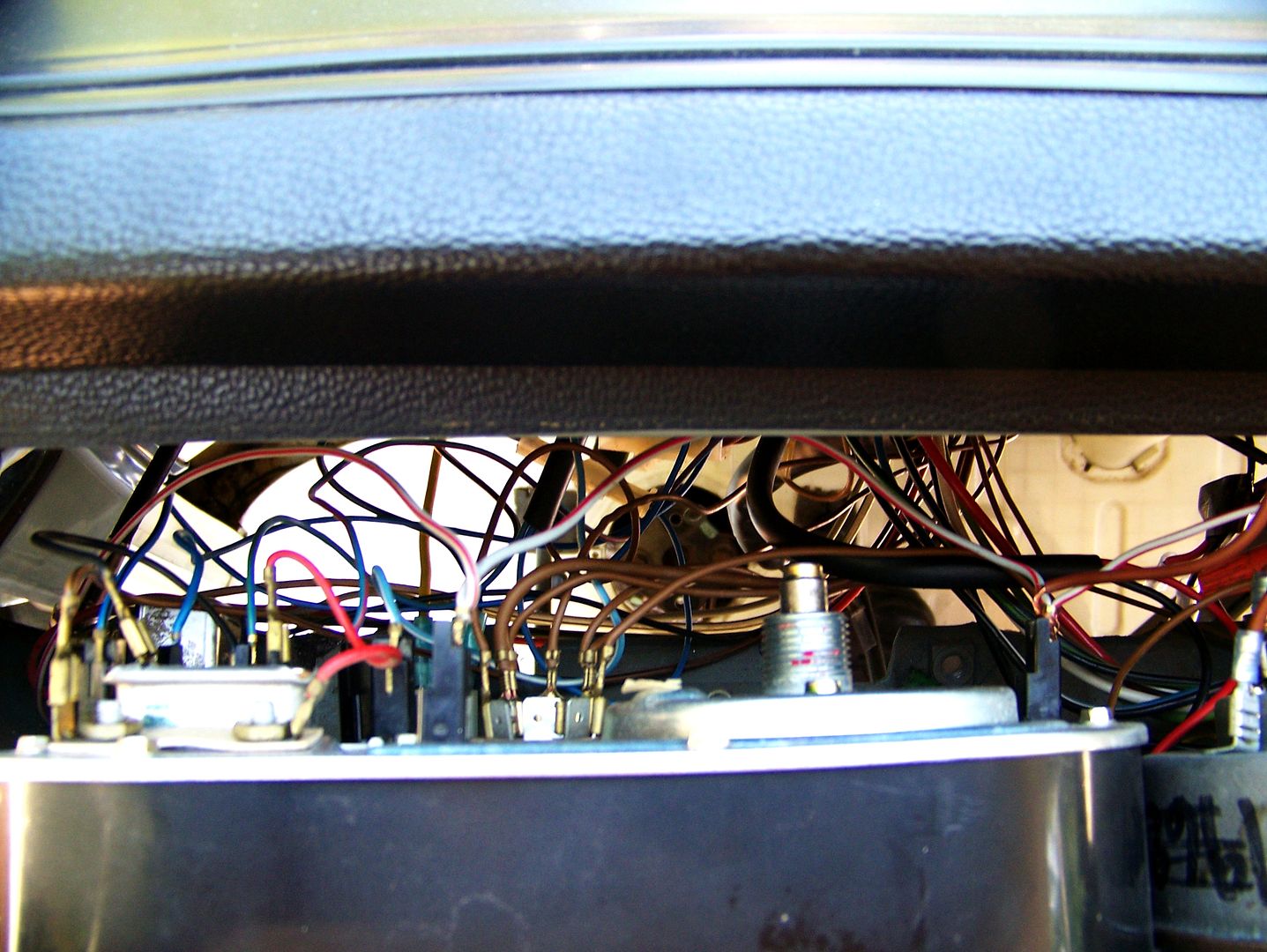

The bus is having lots of electrical weirdness, so I decided to a little investigation into the rats nest of wires under the dash. I knew there had been an electrical fire there at one time, because I found tons of residue from the fire extinguisher that was used to put it out when I took the upper dash off to refresh the wiper motor, and I had seen some burnt paint and melted wire casing.

But the corrosion I found in the fuse box was a little surprising:

The parking lights up front haven't been working, the brake lights are iffy, the left side high beam doesn't activate, and the turn signals are schizo. Now I know why. Several wires have melted casing in places, but no metal/wire is exposed.

I can label and remove every wire, clean up the fuse box, and refit, but what do I use to clean the connectors? An emery board is too big to get in and file the inside of the connector, and I can't imagine trying to sandpaper out each one. Would battery terminal cleaner work? What is causing this corrosion?

Suggestions welcome. Also, maybe someone could submit a photo of how these wires were originally bundled so it doesn't look like spaghetti under there when I am done.

Tim

78 Westy 59,000 miles

Re: Fuse box corrosion

Posted: Sun Jan 06, 2013 11:54 am

by Amskeptic

satchmo wrote:residue from the fire extinguisher

corrosion was a little surprising:

Also, maybe someone could submit a photo of how these wires were originally bundled so it doesn't look like spaghetti under there when I am done.

That corrosion looks a lot like fire extinguisher salts attacking the copper.

Label each wire in alphanumeric order right across the fuse box where

letter = fuse position (a =1 b=2 etc)

number = upper (odd)or lower (even) terminal

(piggyback terminals just double digit 22 or 55 or whatever).

Take the fuse box out and yes, clean each spade and each fuse end with 800 grit sand paper.

DeOx gel each spade and fuse end. As you reinstall wires, smear the DeOx gel tracks on the females.

Now you get the delicious opportunity to re-route wires logically. I did this with the BobD after removing the dash panel.

All brown grounds were placed at a similar elevation, all blue indicator/warning lamp wires were grouped to the main harness going back to the engine, all illumination wires (grey-red) were run along the top, and there were countless un-knots required. What does it say that I enjoyed this operation.

Colin

Re: Fuse box corrosion

Posted: Sun Jan 06, 2013 12:44 pm

by satchmo

Where does one get this DeOx gel of which you speak? I have never seen it in any FLAPS. I've only seen the dielectric tune-up grease by Permatex.

Tim

Re: Fuse box corrosion

Posted: Sun Jan 06, 2013 2:16 pm

by Amskeptic

satchmo wrote:Where does one get this DeOx gel of which you speak? I have never seen it in any FLAPS. I've only seen the dielectric tune-up grease by Permatex.

Tim

Yes . . . dielectric grease.

Colin

Re: Fuse box corrosion

Posted: Sun Jan 06, 2013 9:32 pm

by hambone

I have seen old de-ox jell bonding with centuries of dust and droppings and acting as an insulator.

Re: Fuse box corrosion

Posted: Sun Jan 20, 2013 8:41 pm

by satchmo

I got the corroded fuse box changed out and all the electrical gremlins are resolving slowly. The replacement AFM needed to be exercised, so I took a trip to Joshua Tree National Park for a little desert biking - a new sport I just invented. Range is limited by the amount of spare inner tubes one must carry on account of all the cactus spines you roll over. Anyway, the new-to-me AFM worked well with none of the hiccuping I had near San Fransisco. I thought my CHTs were a little high (400* cruising at 3500 rpm), so I made things a little richer on the dynamic adjustment, which helped the CHT, but I got only 14.4 mpg on my way home. So more adjustment will be done soon.

The fast idle on cold starts has disappeared as well, for no reason that I can identify. I know the AAR is working as it should with lots of vacuum pull at start-up then going to almost no air passing after a few minutes. I tried two different Temp II sensors and that didn't help either. The Bentley says the Temp II should be 2500 ohms when grounded at the connector, but they don't say at what temperature the reading should be taken. I imagine that makes a difference, right? I got over 4000 ohms when I first checked it this morning and then later in the day I had a reading closer to 3000 ohms. Neither Temp II sensor I installed seems in spec but maybe I wasn't taking the reading at 75* ambient if that is what is necessary.

I was by myself camping at Joshua Tree. Not many other people there who would take any time to step out of their RVs and brave the cold. Each morning, however, I would awaken and find this face staring at me:

I started calling him "Wilson" and we had some interesting conversations.

I nearly froze my arse off at Joshua Tree. It gets really cold when the sun goes down. Sweatshirt, down jacket and two sleeping bags were needed to keep me from shivering. I must be getting hypothermic as I age. There is no wood available in the desert for a decent fire, at least not within a half mile radius of the campground at which I was located (Jumbo Rocks). You aren't supposed to pick up any dead plant material in the National Park anyway. I made a fire one night with sticks I had in the bus and a little log I walked about a mile to find. Don't tell Mr. Ranger.

Tim

78 Westy

Re: Fuse box corrosion

Posted: Sun Jan 20, 2013 9:16 pm

by Elwood

Love the face !!!! and was thinking about you in JT--- great place !

Was freezing cold in my cabin--- all pipes froze for 4days , forgot some of my survivor skills to get water. Had to drain hotwater heater on 5th day.

thanks for sharring.

Re: Fuse box corrosion

Posted: Mon Jan 21, 2013 3:34 pm

by ruckman101

Corrosion on my fuse box has been from the windshield leaking and dripping onto it. But that's pretty easy to spot.

neal