The reason I burned three valves is because I had made a bad decision that affected all of my clackityclacky valves. The valve stems were a bit stoved in from both the approximately 70,000 miles since the prior rebuild and the fact that the rockers had not been shimmed to ensure that the adjustment screws were slightly off-center . A flat feeler blade only contacts the outer circumference of a stoved in stem and covers up the "bowl" underneath. Even with a serious drag on the blade, the adjustment screws were pounding the centers of the bowls. I don't remember exactly what decision I made to compensate, but it was wrong . . .

. . . yesterday, I realized that I have some valve stems on Chloe that are a bit caved in as well. The engine had developed quite a tackitytack at idle, even with draggy feeler blades. So I thought to create a new method of valve adjustment that would be similar to the hydraulic valve adjustment method, so I would not have a feeler blade acting as a plank over a bowl.

If the valve adjustment screws are a 1.00mm pitch, and our adjustment specification is .15mm (.006"), why not back the screw out a precise number of degrees? Then I won't get thrown by a dished stem.

1mm pitch / 360º = .0027 X 55º = .015mm required clearance.

So, that is what I did.

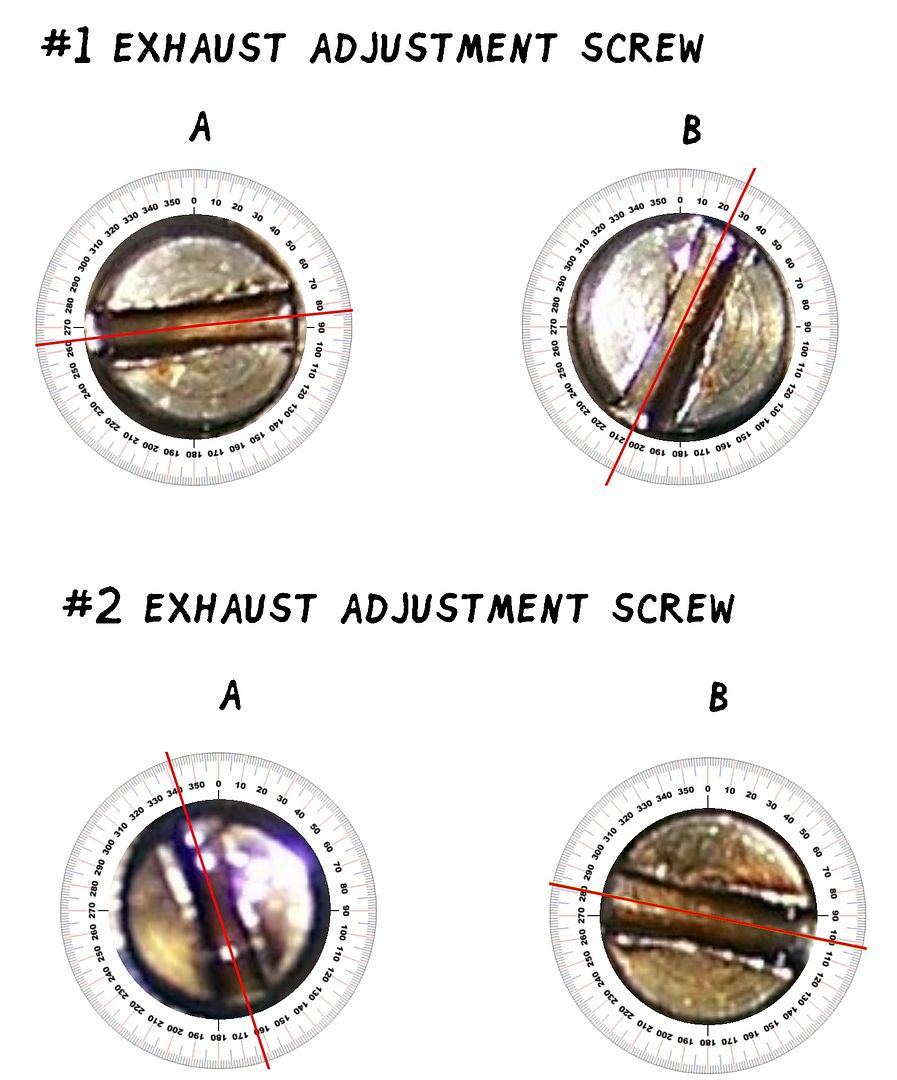

A turn adjustment screw with fingers until it contacts valve stem

B turn backwards 55º (I did 60º)

(I will bring a spare set of heads* with me, just in case I have screwed up again):

*the heads that were originally on my engine got their seats destroyed by too-small fuel injected beetle exhaust valves. Now they are languishing in a box with new Osvat exhaust valves and new exhaust seats that hopefully will know how to stay in place. I have never owned or driven a VW with replacement seats . . . but if this experiment goes awry, the above *heads will have their next chance to hit the road.