Page 1 of 1

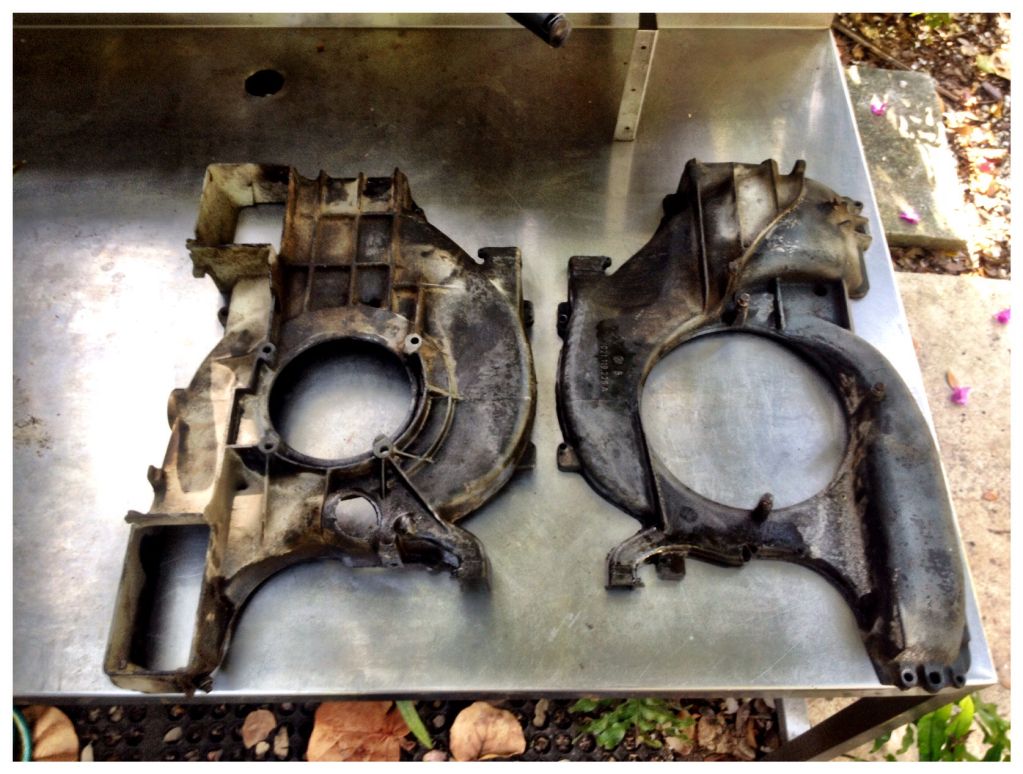

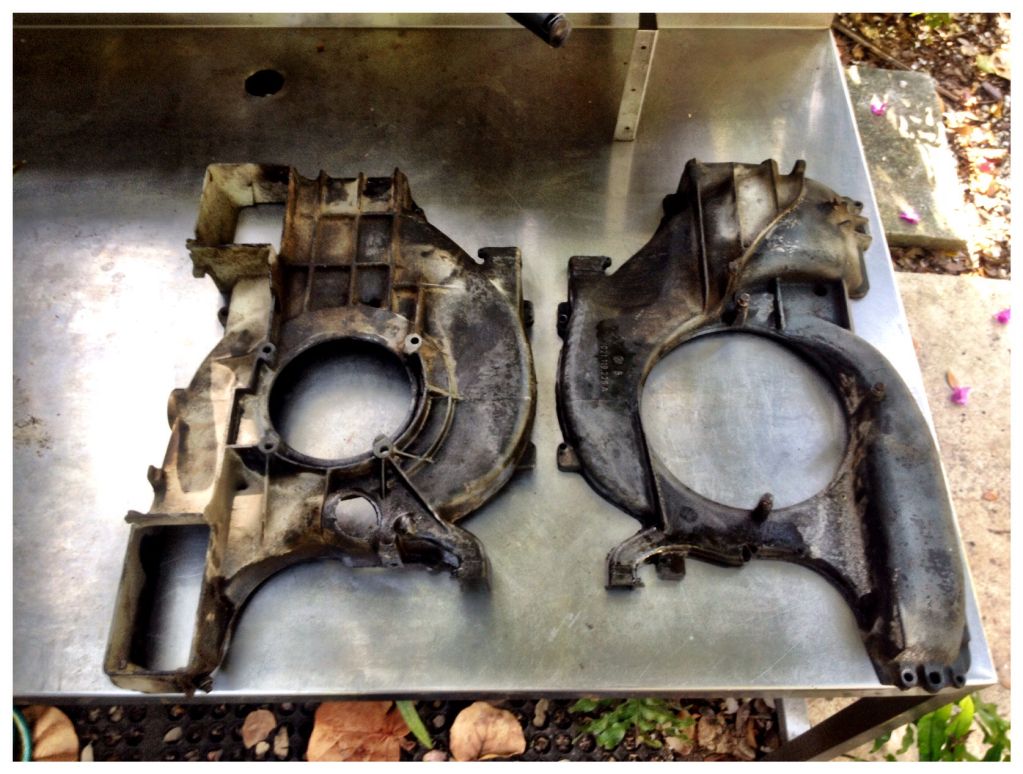

Fan shroud problem.

Posted: Fri Jun 20, 2014 10:05 am

by Jivermo

I'm trying to get my type 4 shroud apart, but the dipstick tube refuses to budge. Any secrets here; does it tap out a certain way?

Re: Fan shroud problem.

Posted: Fri Jun 20, 2014 9:32 pm

by airkooledchris

Rubber hammer and a lot of patience. It'll eventually start to slide it's way out, but you'll scare yourself into thinking your breaking it before that happens. just pay close attention to the angle at which is goes through the halves so you know how to wiggle it the right way.

Re: Fan shroud problem.

Posted: Fri Jun 20, 2014 11:05 pm

by Amskeptic

airkooledchris wrote:Rubber hammer and a lot of patience. It'll eventually start to slide it's way out, but you'll scare yourself into thinking your breaking it before that happens. just pay close attention to the angle at which is goes through the halves so you know how to wiggle it the right way.

Stick a long bolt of correct diameter into the pipe so your hits are guaranteed to not distort the tube?

Colin

Re: Fan shroud problem.

Posted: Sat Jun 21, 2014 10:14 am

by Jivermo

Finally got it...used both of the tips given to jar it loose. Man, do I have the hours in this thing, or what? Doing a rebuild has definitely got to be a labor of love. New appreciation of the labors of Sisyphus.

Re: Fan shroud problem.

Posted: Sat Jun 21, 2014 12:22 pm

by ruckman101

Tedious with detail.

neal

Re: Fan shroud problem.

Posted: Mon Jun 23, 2014 8:57 am

by Amskeptic

Jivermo wrote:Doing a rebuild has definitely got to be a labor of love. New appreciation of the labors of Sisyphus.

It is a labor of love. You look at those parts that served you. You remember those drives they gave you.

I don't think you get the Sisyphean award yet. Sisyphean is when you have to re-rebuild it because you set the end play a smidge tight, so you have to re-rebuild it with new main bearings but the cam thrust bearing was out of spec so you have to re-re-rebuild it.

I love it. There is nothing but the joy of springtime for the engine . . .

DaftyDuck

Re: Fan shroud problem.

Posted: Mon Jun 23, 2014 10:42 am

by airkooledchris

Once you start down the path, your start realizing just far it really goes.

3 months later your wondering how much time you should spend detailing your fuel pressure regulator, lest it look ugly and unmatched to the cleanliness and shininess of the bits around it.

If I was to make any suggestions - it would be to take advantage of your friendly local machine shop. If your going to drop off your flywheel and pressure plate for resurfacing/balancing - bring all of your tinware and fan shroud with. They can dip it and/or clean it up for you nice so it's near-ready for paint. Then save your final painting of the tinware for after a test fitment, so you can massage it into shape without worrying about scratching your nicely finished pieces. (but do put something on them so they aren't in bare metal too long and collecting rust).

Re: Fan shroud problem.

Posted: Wed Jun 25, 2014 9:17 am

by Amskeptic

airkooledchris wrote:Once you start down the path, your start realizing just far it really goes.

3 months later your wondering how much time you should spend detailing your fuel pressure regulator, lest it look ugly and unmatched to the cleanliness and shininess of the bits around it.

If I was to make any suggestions - it would be to take advantage of your friendly local machine shop. If your going to drop off your flywheel and pressure plate for resurfacing/balancing - bring all of your tinware and fan shroud with. They can dip it and/or clean it up for you nice so it's near-ready for paint. Then save your final painting of the tinware for after a test fitment, so you can massage it into shape without worrying about scratching your nicely finished pieces. (but do put something on them so they aren't in bare metal too long and collecting rust).

What he said . . .

Colin =D>