I get a measurement of .354 inches of total travel, so my rocker arm should be parallel at .177 inches, but eyeballing it seems less than accurate. I mean it looks pretty good, but ... . Striving for "just exactly perfect".

thanks,

neal

Relax. Eyeball it. You can *see* the arc of the screw enter into parallel with the valve stem. THEN measure exactly half lift backwards towards closed. If it is clicky, it was "not enough" at half-lift. If it is still under pressure then it was "too much" at half lift.ruckman101 wrote:How do I do this? Striving for "just exactly perfect".

thanks,

neal

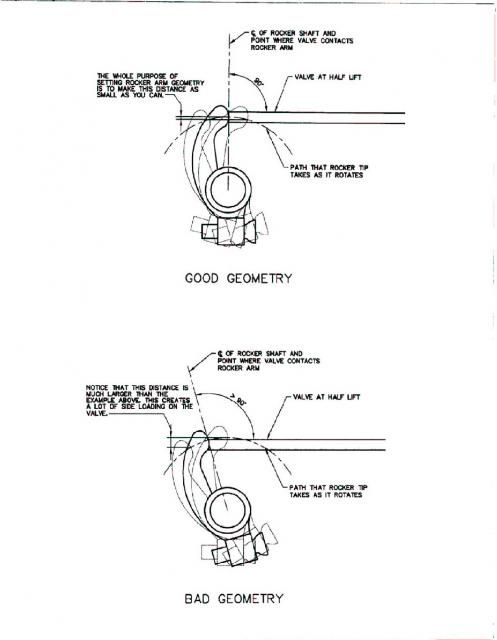

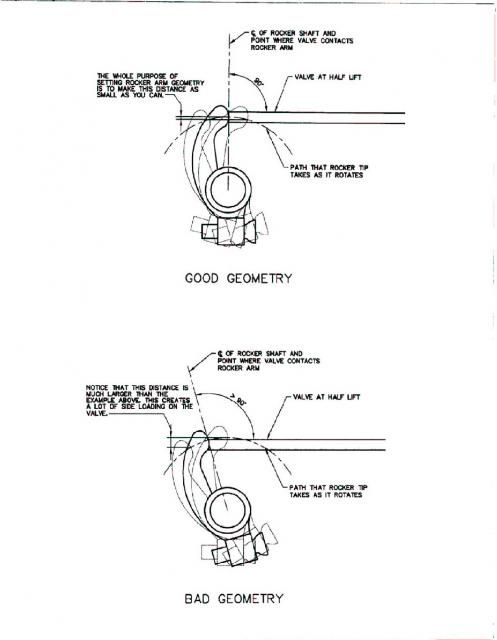

I do. That is where it operates. If you get rid of all clearance, the screw is further in the rocker arm. If you set the mid-lift parallel here, then back the screw off to get clearance, then your actual mid-lift is going to be applying a slight downwards pressure on the valve stem. Visualize it. You have the perfect parallel with no clearance. OK. When you subsequently adjust for .006" clearance, the screw is now *away*. The rocker arm has to travel in further to touch, then open the valve. That means you will be past parallel at mid-lift. Ergo, adjustment screw is beginning to arc downwards, valve is now spending too much time slightly downwards.ruckman101 wrote:Clicky? You mean I shouldn't have the normal gap while making this assessment?

neal

Xelmon wrote:Now that I looked at it, I havez a better idea what you are looking at too.

Oh... OOoooooohhhh, right, that makes sense! I didn't eve think of that, was still in the coffee daze of the morning.Amskeptic wrote:This is not at all about the orientation of the push rod to rocker arm.Xelmon wrote:Now that I looked at it, I havez a better idea what you are looking at too.

It is solely to keep side loads on the brass/phosphur bronze valve guides to a minimum.

"Bushings"? Belt down another coffee . . .Xelmon wrote: Really, bushings are that soft? Hm, good to know.

... Did I seriously misread that that badly? Seems like it, yesterday was a bit of a madhouse and a twiddling thumbs kind of day all in one.Amskeptic wrote:Valve guides have to be able to work with very little lubrication. Bronze-phosphor guides can function well in a limited lubrication environment such as a VW with valve stems that point UP! towards the combustion chambers, and better yet, bronze can conduct heat pretty well which makes the exhaust valves happy. The downside is that bronze is a tad soft in relation to steel valves. We VW people must execute due diligence here, VW heads have to work extremely hard in most every way.Xelmon wrote: Really, bushings are that soft? Hm, good to know.

Colin