CR Struggles

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

CR Struggles

Math is my weakest subject. I've tried online formulas with plug in values, but the results have been insultingly other world inaccurate.

Standard stroke is 69 mm, 85.5 pistons. Pi is needed, no? 85.5 x pi x 69, no? plus combustion chamber volume for total displacement then divided by the total less the stroke volume, yes?

neal

Standard stroke is 69 mm, 85.5 pistons. Pi is needed, no? 85.5 x pi x 69, no? plus combustion chamber volume for total displacement then divided by the total less the stroke volume, yes?

neal

The slipper has no teeth.

-

kreemoweet

- Getting Hooked!

- Location: Seattle

- Status: Offline

Re: CR Struggles

Here's an on-line calculator, no pi needed, no math needed, just make sure the units are correct:

http://www.summitracing.com/expertadvic ... calculator.

I just tested it, it works fine. Put 0 for head gasket thickness and dome/dish volume.

http://www.summitracing.com/expertadvic ... calculator.

I just tested it, it works fine. Put 0 for head gasket thickness and dome/dish volume.

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

- Amskeptic

- IAC "Help Desk"

- Status: Offline

Re: CR Struggles

So let's talk about compression ratios . . .

In the 50's, the famous VW longevity recipe called for 6.6 ratio with the then limits of metallurgical performance.

As need for power increased, CR was 7.7 in the middle '60s when mixtures were allowed to help cool the engine.

The first year of lean highway emissions requirement (1970), CR was dropped to 7.5 for cooling.

The next jump in lean emissions requirement was 1973 when VW dropped the compression ratio down to 7.3, primarily to drop NOX.

7.3 has been the chosen ratio from 1973 the the end of the model run. It is a good ratio for air-cooled engines with lean mixtures, and the babble about increasing the compression ratio for better power has often ignored the hit against both longevity and smoothness.

If you have a 1970/71 1600, stick with the 7.5.

Colin

In the 50's, the famous VW longevity recipe called for 6.6 ratio with the then limits of metallurgical performance.

As need for power increased, CR was 7.7 in the middle '60s when mixtures were allowed to help cool the engine.

The first year of lean highway emissions requirement (1970), CR was dropped to 7.5 for cooling.

The next jump in lean emissions requirement was 1973 when VW dropped the compression ratio down to 7.3, primarily to drop NOX.

7.3 has been the chosen ratio from 1973 the the end of the model run. It is a good ratio for air-cooled engines with lean mixtures, and the babble about increasing the compression ratio for better power has often ignored the hit against both longevity and smoothness.

If you have a 1970/71 1600, stick with the 7.5.

Colin

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: CR Struggles

Thank you, you've anticipated my next question. I've heard suggest that with the 10 percent alcohol fuel mix now standard year round here an even lower CR might be wise. Cylinder mounting surfaces were machined down .015, so have two sets of .010 shims to play with, also.

neal

neal

The slipper has no teeth.

- Amskeptic

- IAC "Help Desk"

- Status: Offline

Re: CR Struggles

No need to go lower. Alcohol is a cool slow burner, who said it was more volatile? NAMES Pure ethanol comes in at about 100 octane.ruckman101 wrote:Thank you, you've anticipated my next question. I've heard suggest that with the 10 percent alcohol fuel mix now standard year round here an even lower CR might be wise. Cylinder mounting surfaces were machined down .015, so have two sets of .010 shims to play with, also.

neal

You can play with the timing I have been at 3* ATDC with Chloe, very happy little engine with decent compression, 135/140/125/145.

Slightly lazy on the road, but who around here is in some sort of a hurry to DRIVE 21,019 MILES IN 23 WEEKS ??

Colin

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: CR Struggles

My deck height without shims is .047" Base paper gasket is .008".

If I use two .010" base shims, total deck height is .075".

CR comes in at 7.9 : 1 on the 3/4 side with combustion chamber volumes of 46cc,

and 8.1 : 1 on the 1/2 side with combustion chamber volumes of 45 cc.

If I leave off the paper gasket on the 3/4 side, I get 8:1. Is this acceptable?

neal/colin

If I use two .010" base shims, total deck height is .075".

CR comes in at 7.9 : 1 on the 3/4 side with combustion chamber volumes of 46cc,

and 8.1 : 1 on the 1/2 side with combustion chamber volumes of 45 cc.

If I leave off the paper gasket on the 3/4 side, I get 8:1. Is this acceptable?

neal/colin

The slipper has no teeth.

- Amskeptic

- IAC "Help Desk"

- Status: Offline

Re: CR Struggles

ruckman101 wrote:My deck height without shims is .047" Base paper gasket is .008".

If I use two .010" base shims, total deck height is .075".

CR comes in at 7.9 : 1 on the 3/4 side with combustion chamber volumes of 46cc,

and 8.1 : 1 on the 1/2 side with combustion chamber volumes of 45 cc.

If I leave off the paper gasket on the 3/4 side, I get 8:1. Is this acceptable?

You want .060 base shims on the right and .050 base shims on the left for a 7.5 compression ratio.

Air-Cooled.Net has them.

Colin

(p.s. your numbers suggest some serious flycutting has occurred on your heads. These are singleport heads?)

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: CR Struggles

Yes, single port heads. Yes, flycut. Perhaps not the first time. First time I have had them flycut. The machinist step cut them, telling me they had the same volume as original stock heads, and that the volumes were now the same, but not by my crude measurements. Perhaps I should re-measure them.

neal

neal

The slipper has no teeth.

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: CR Struggles

Re-measured. The same. .050 shims on the 1/2 side gives me spot on 7.5:1 =/- measurement errors, and 7.53:1 on the 3/4 side with the paper gasket and .060 shims. I'm good to go as soon as I get the additional shims tomorrow. Thanks for the help all.

neal

neal

The slipper has no teeth.

- Amskeptic

- IAC "Help Desk"

- Status: Offline

Re: CR Struggles

Neal,ruckman101 wrote:Re-measured. The same. .050 shims on the 1/2 side gives me spot on 7.5:1 =/- measurement errors, and 7.53:1 on the 3/4 side with the paper gasket and .060 shims. I'm good to go as soon as I get the additional shims tomorrow. Thanks for the help all.

neal

If the machinist "step-cut" them, are you saying that they have a ledge where the barrels meet the heads, like all the 1973 factory heads?

You best double check your combustion chamber volumes. They have to include all volume right to the ledge. I am expecting 53 ccs off the top of my head.

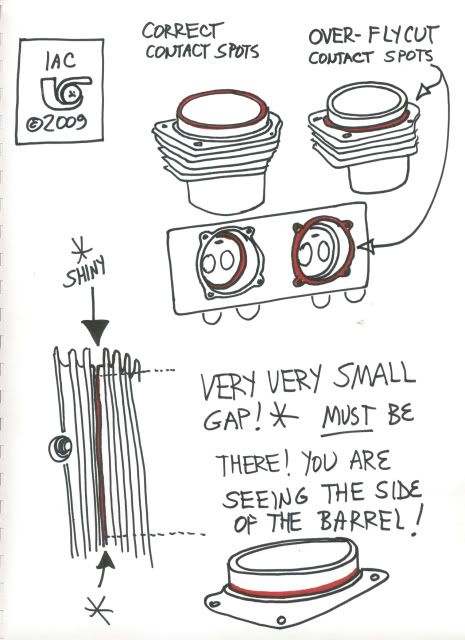

Be absolutely sure that the barrels only contact the head inside the cylinder spigots. You may need to mill the bottoms of the heads to avoid hitting the barrel fin surface. Remember this old Hambone picture?

There is a wealth of info on engine rebuild issues around here, yessirree, yep, sure is . . .

Colin

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

- ruckman101

- Lord God King Bwana

- Location: Up next to a volcano.

- Contact:

- Status: Offline

Re: CR Struggles

Yes, step cut on the machining fly cut. The machinist said he did that to maintain factory spec on the volume of the compression chamber of the heads. I will mention to him my measurements did not confirm his claim that the volume of those chambers was the same on both heads. I don't know what the factory spec is, but of all the measurements I did, probably averaged to 46, 47 cc.

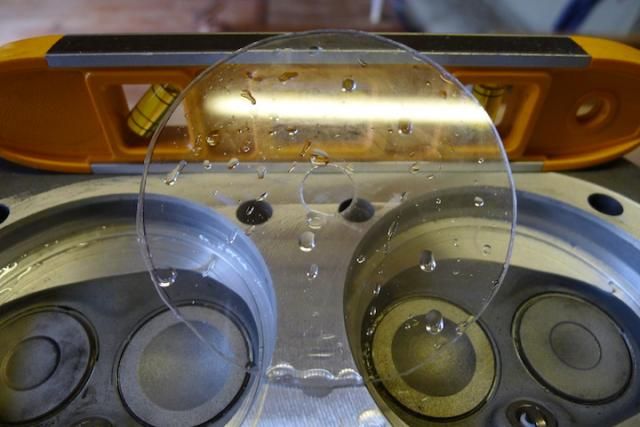

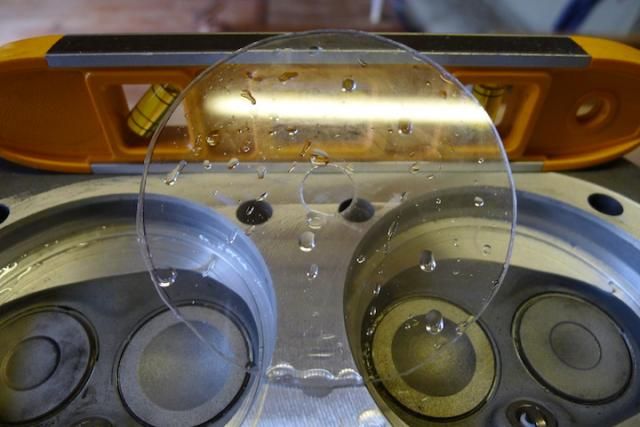

Here's my "as accurate as I could get" measuring technique.

Level head. Craft new specialty tool. That darn surface tension of liquids. Couldn't find my original crafted specialty tool. But a small band saw made pretty quick work of crafting a new one. Lucky to have a suitable bit of plexiglass at hand.

Accurate measuring, is, well, difficult to get just exactly perfect. I did learn the standard is to align the bottom of the fluid curve to the line.

Watch those air bubbles. Push the water on top of the specialty tool into the hole in the middle when you splash.

Eh, did the best I could. Hope the numbers I ended up with more closely represent reality than my lack of confidence in the variables I can do my best to account for. In other words, nothing wildly off.

And notice the machine shop fly cut on the cooling fins. The other head not as much. That was done specifically to address the issue those fantastically clear illustrations pointed out as a concern.

neal

Here's my "as accurate as I could get" measuring technique.

Level head. Craft new specialty tool. That darn surface tension of liquids. Couldn't find my original crafted specialty tool. But a small band saw made pretty quick work of crafting a new one. Lucky to have a suitable bit of plexiglass at hand.

Accurate measuring, is, well, difficult to get just exactly perfect. I did learn the standard is to align the bottom of the fluid curve to the line.

Watch those air bubbles. Push the water on top of the specialty tool into the hole in the middle when you splash.

Eh, did the best I could. Hope the numbers I ended up with more closely represent reality than my lack of confidence in the variables I can do my best to account for. In other words, nothing wildly off.

And notice the machine shop fly cut on the cooling fins. The other head not as much. That was done specifically to address the issue those fantastically clear illustrations pointed out as a concern.

neal

The slipper has no teeth.

- Bleyseng

- IAC Addict!

- Location: Seattle again

- Contact:

- Status: Offline

Re: CR Struggles

Don't use water, use mineral oil.....

Geoff

77 Sage Green Westy- CS 2.0L-160,000 miles

70 Ghia vert, black, stock 1600SP,- 139,000 miles,

76 914 2.1L-Nepal Orange- 160,000+ miles

http://bleysengaway.blogspot.com/

77 Sage Green Westy- CS 2.0L-160,000 miles

70 Ghia vert, black, stock 1600SP,- 139,000 miles,

76 914 2.1L-Nepal Orange- 160,000+ miles

http://bleysengaway.blogspot.com/

- Amskeptic

- IAC "Help Desk"

- Status: Offline

Re: CR Struggles

Let us work on our grammar and spelling, shall we, Bleyseng, you know, to help this site be a refreshingly communicative beacon of enlightenment?Bleyseng wrote:Don't is water use mineral oil.....

Thanx

Neal, I used windshield washer fluid to break the surface tension for "streak-free" results.

I am concerned about all the cutting. Glad to see that the bottom surface of the head was milled to keep the spigot depth within bounds.

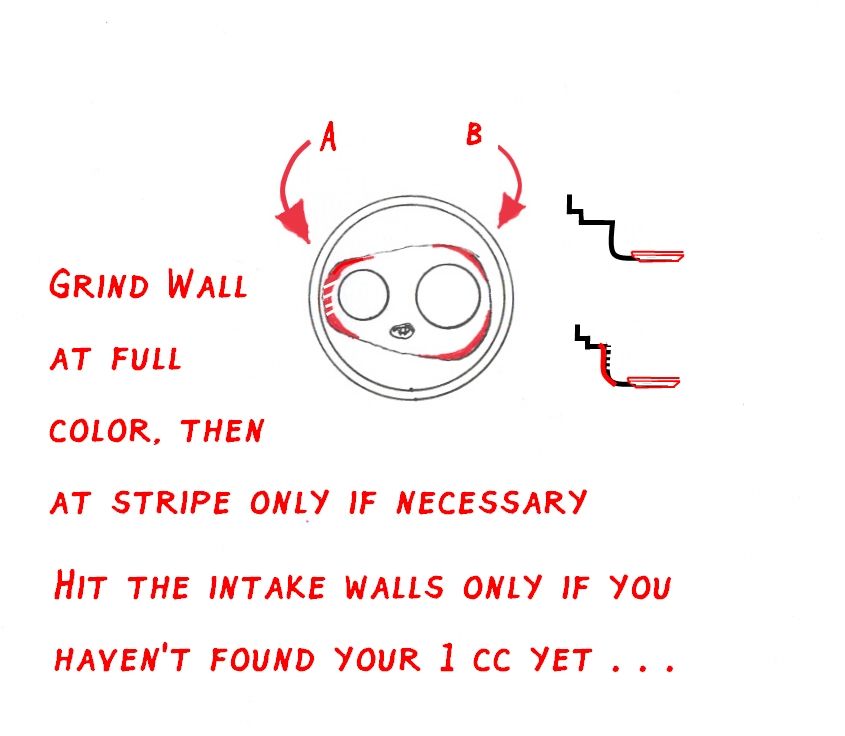

You can find a cc on the right head by opening up the radius around the exhaust valve. This has the added benefit of "un-shrouding" the exhaust valve seat which reduces the local velocity of the hot gases passing around the open exhaust valve into the port.

BobD - 78 Bus . . . 112,730 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

Chloe - 70 bus . . . 217,593 miles

Naranja - 77 Westy . . . 142,970 miles

Pluck - 1973 Squareback . . . . . . 55,600 miles

Alexus - 91 Lexus LS400 . . . 96,675 miles

- Bleyseng

- IAC Addict!

- Location: Seattle again

- Contact:

- Status: Offline

Re: CR Struggles

Ok, I'll try but I have next to nothing skills as a writer compared to you or IBXwax. Plus its devolved since trying to learn Dutch grammar for the last 4 years.

In English this would be a Dutch sentence: "Ok, I next to nothing try have".

Back on topic, use Mineral oil to cc the heads and carefully balance the combustion chambers as illustrated by Colin's beautiful picture. Go slow with the grinding as it doesn't take much to remove too much quickly.

In English this would be a Dutch sentence: "Ok, I next to nothing try have".

Back on topic, use Mineral oil to cc the heads and carefully balance the combustion chambers as illustrated by Colin's beautiful picture. Go slow with the grinding as it doesn't take much to remove too much quickly.

Geoff

77 Sage Green Westy- CS 2.0L-160,000 miles

70 Ghia vert, black, stock 1600SP,- 139,000 miles,

76 914 2.1L-Nepal Orange- 160,000+ miles

http://bleysengaway.blogspot.com/

77 Sage Green Westy- CS 2.0L-160,000 miles

70 Ghia vert, black, stock 1600SP,- 139,000 miles,

76 914 2.1L-Nepal Orange- 160,000+ miles

http://bleysengaway.blogspot.com/