Really really really annoying as I had the drive-train balanced as a unit. Pistons, connecting rods, pulley, flywheel and pressure plate to the crankshaft.

Got the engine pulled today and I certainly got the pressure plate properly mated to the flywheel based on the yellow marks.

So how about flywheel to crankshaft.

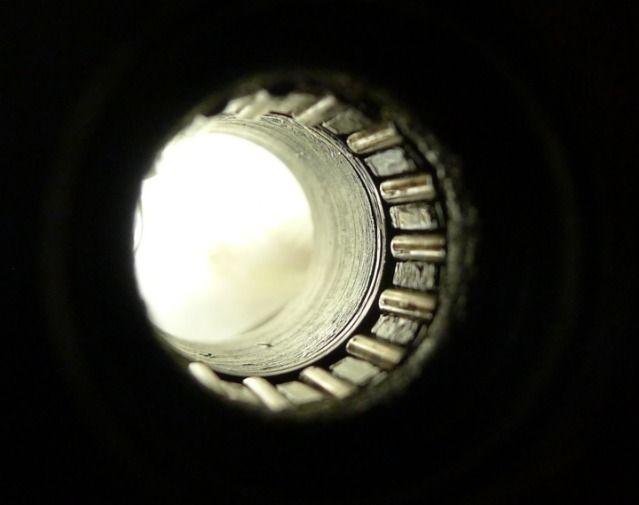

Yep. Gland nut isn't showing any visible cracks or issues.

So I'm scratching my head. Should I not have used the paper gasket?

Only thing left is the clutch plate itself.

Hmmmm. What the hell is that thing? Why? Whafor? Could that be it? A rubbery chunk of something. None of the other springs seem to have a rubbery chunk, so I don't think it worked out of just the one spring, didn't see anything on the other springs. Is the rubber part of the clutch plate assembly?

neal